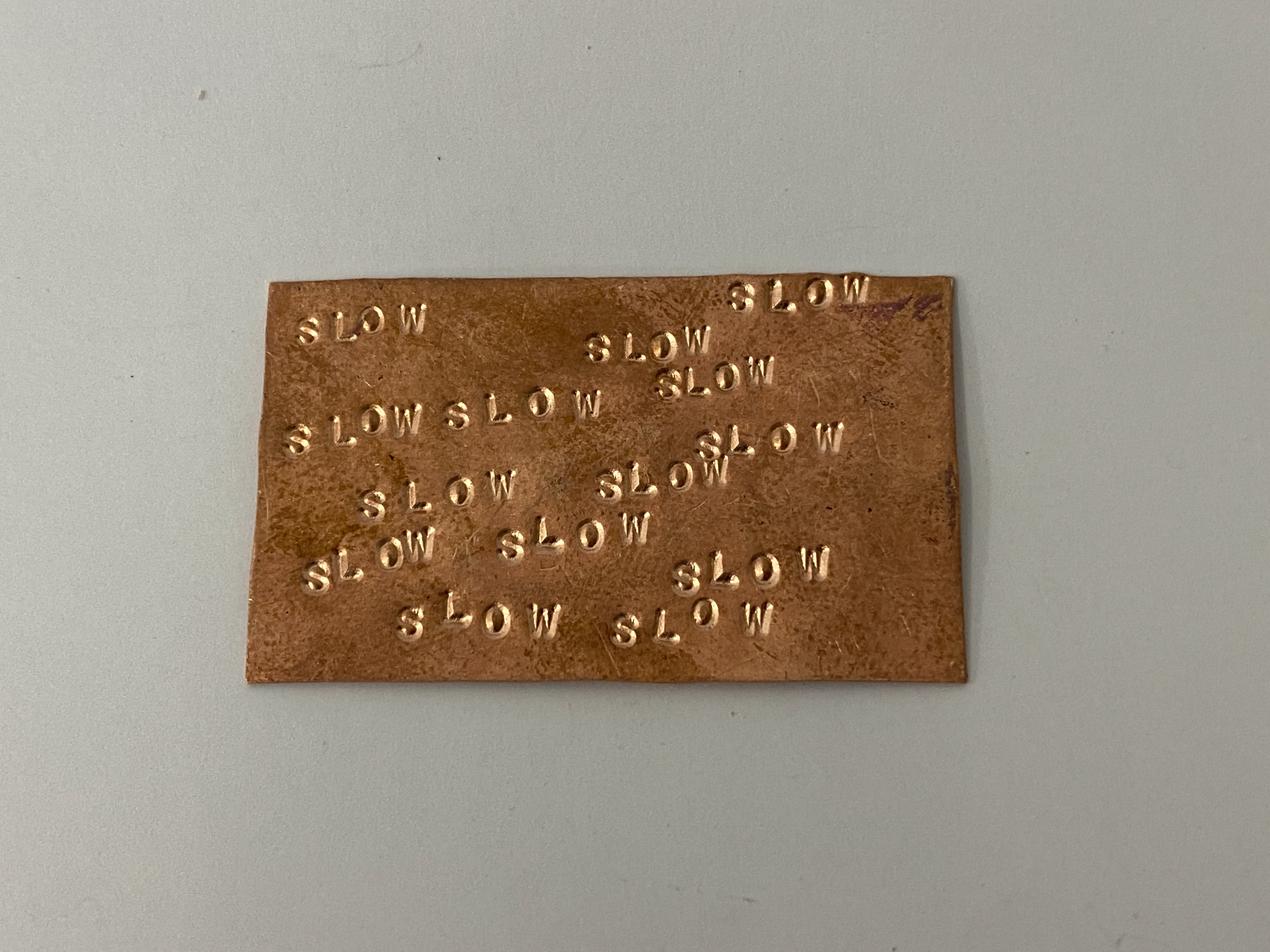

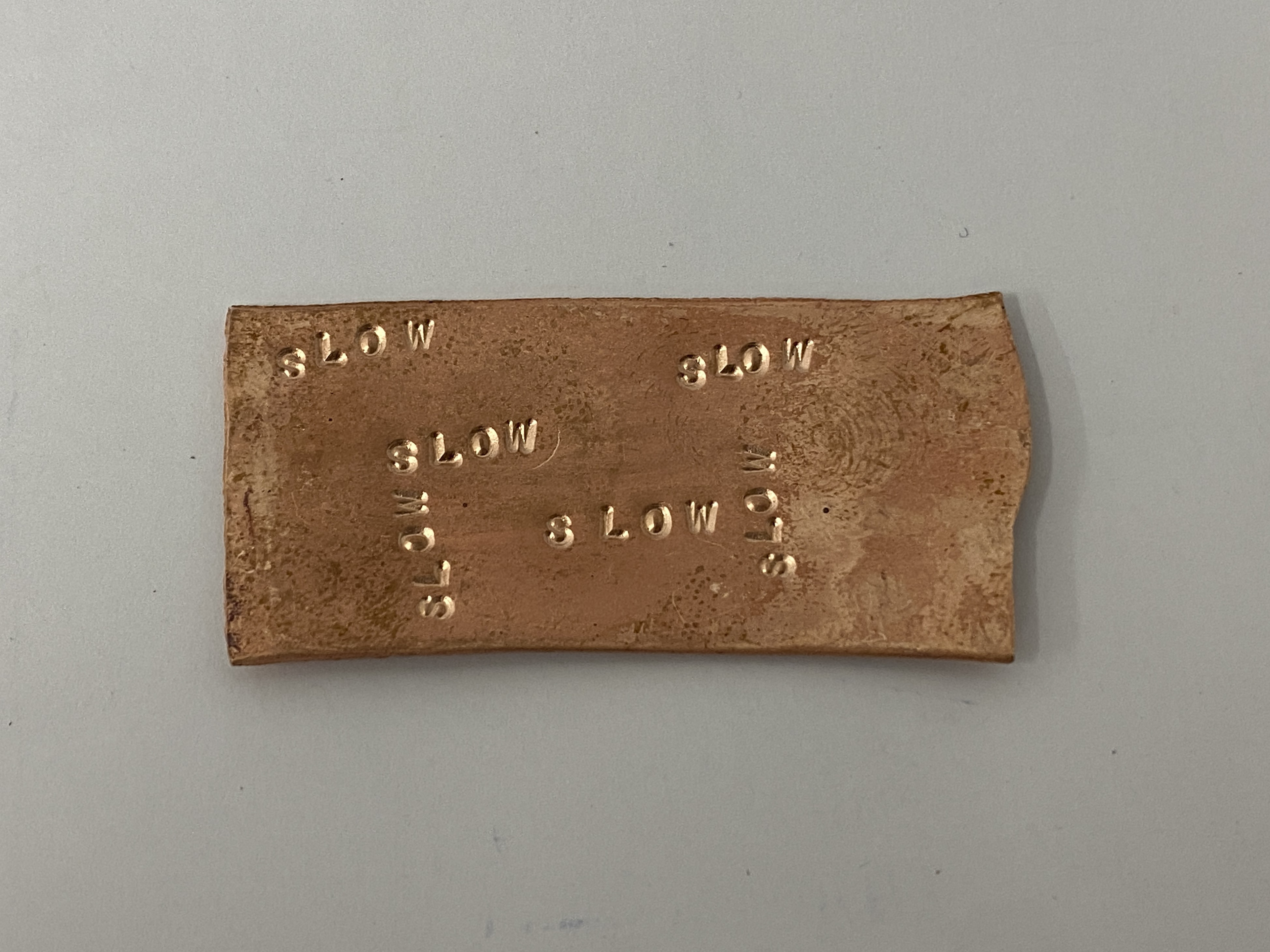

Having previously experimented with letter stamping into copper sheet I only did a few tests to explore how changing the placement of a repeated word altered the overall composition. I discovered that I could use a crowded design to overwhelm the user whereas negative space puts higher emphasis on the word itself. I also played with overlaying the word and lettered to obscure and censor the message.

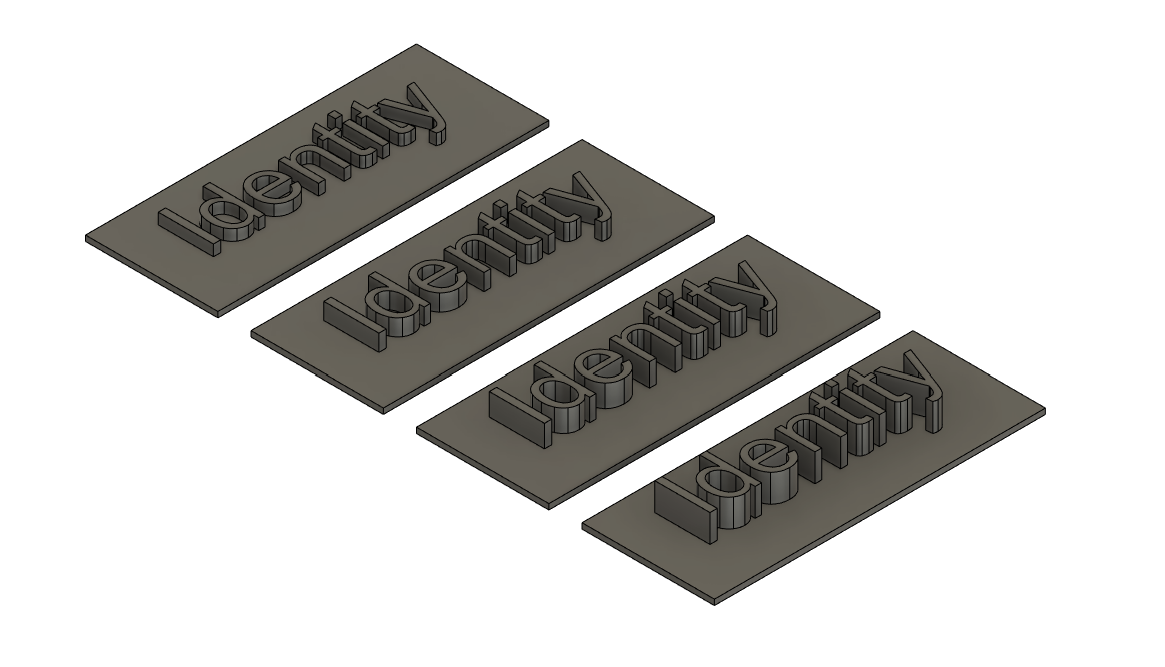

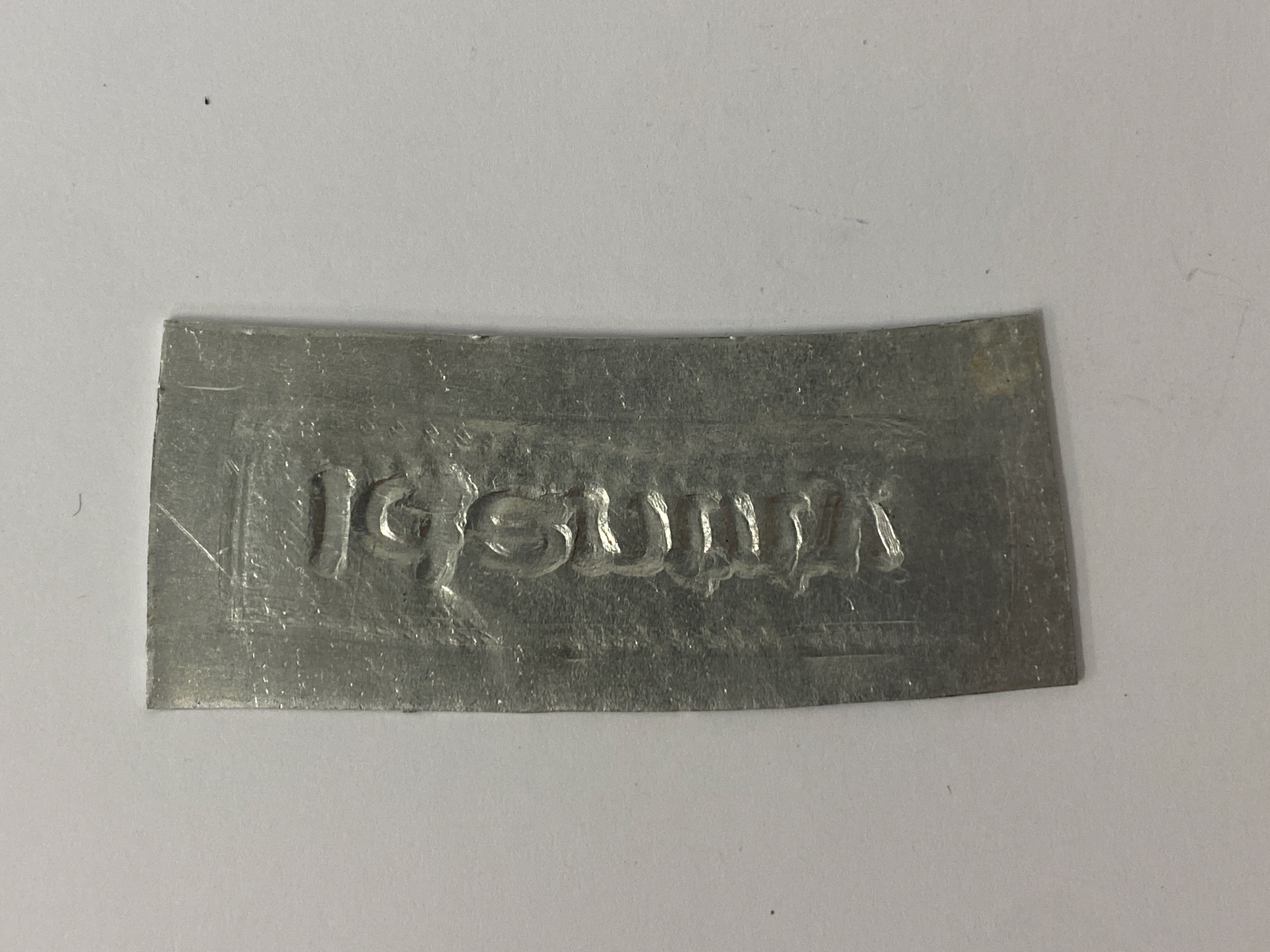

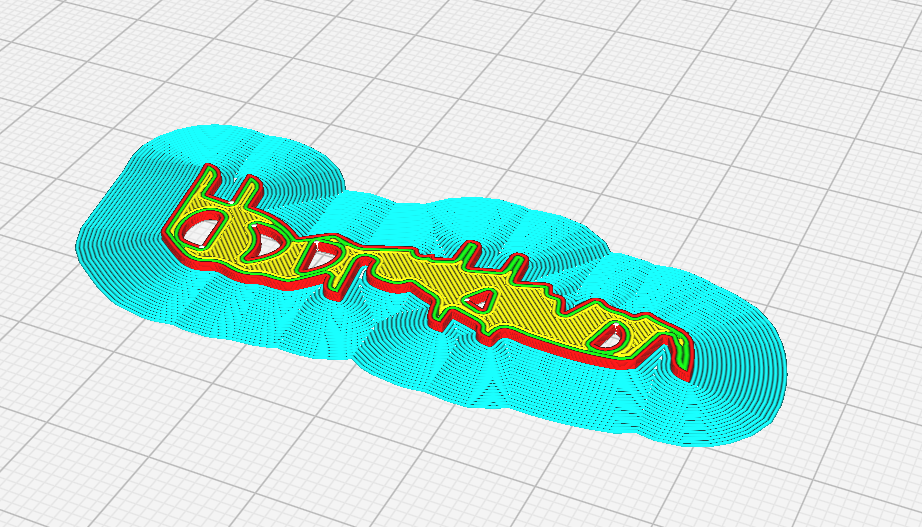

To investigate the idea of distortion and censorship further I designed so sacrificial texture plates to be rolled onto metal. The rolling process compresses and stretches texture plates and thus distorting the original design. I created a variety of sized words (5, 10, 15, 20mm) and letter depth (1, 1.5, 2, 2.5mm) to be 3D printed to test what the best size gave the clearest or coherent print.

1mm

1.5mm

2mm

2.5mm

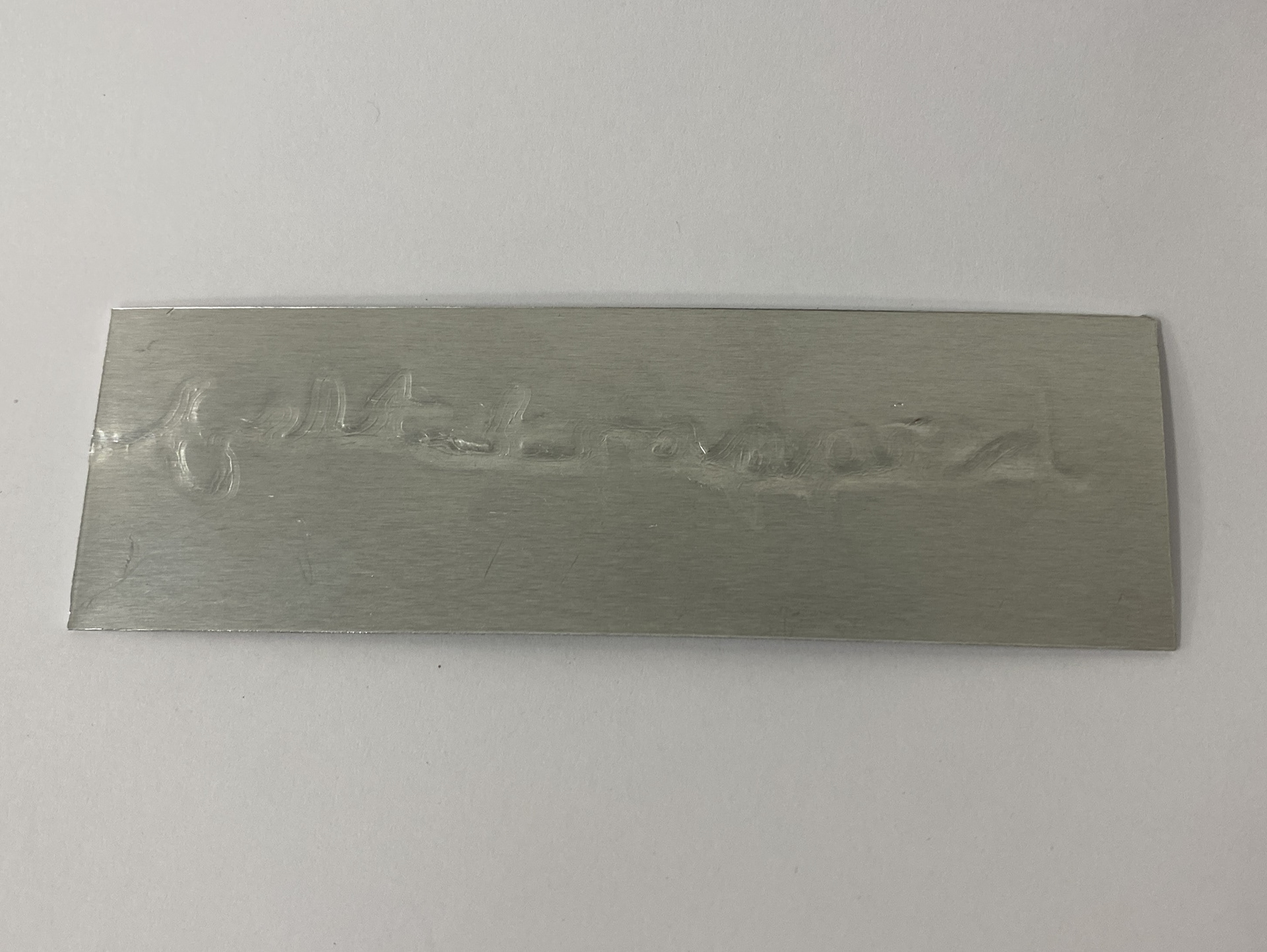

Initial testing led me to find that the PLA plastic that I was using to 3D print the words onto didnt have enough compressive strength (dispite me using 100% infill when printing) to leave a noticable mark on annealed copper. Therefore, I tried aluminium which worked much better and I found that 1mm deep letters gave the clearest imprint. Also, the deeper the letters the more the roller distorts it as the layer lines of the print fold over and squish outwards. However, going too thick results in the plastic crushing onto itself rather than into the aluminium.

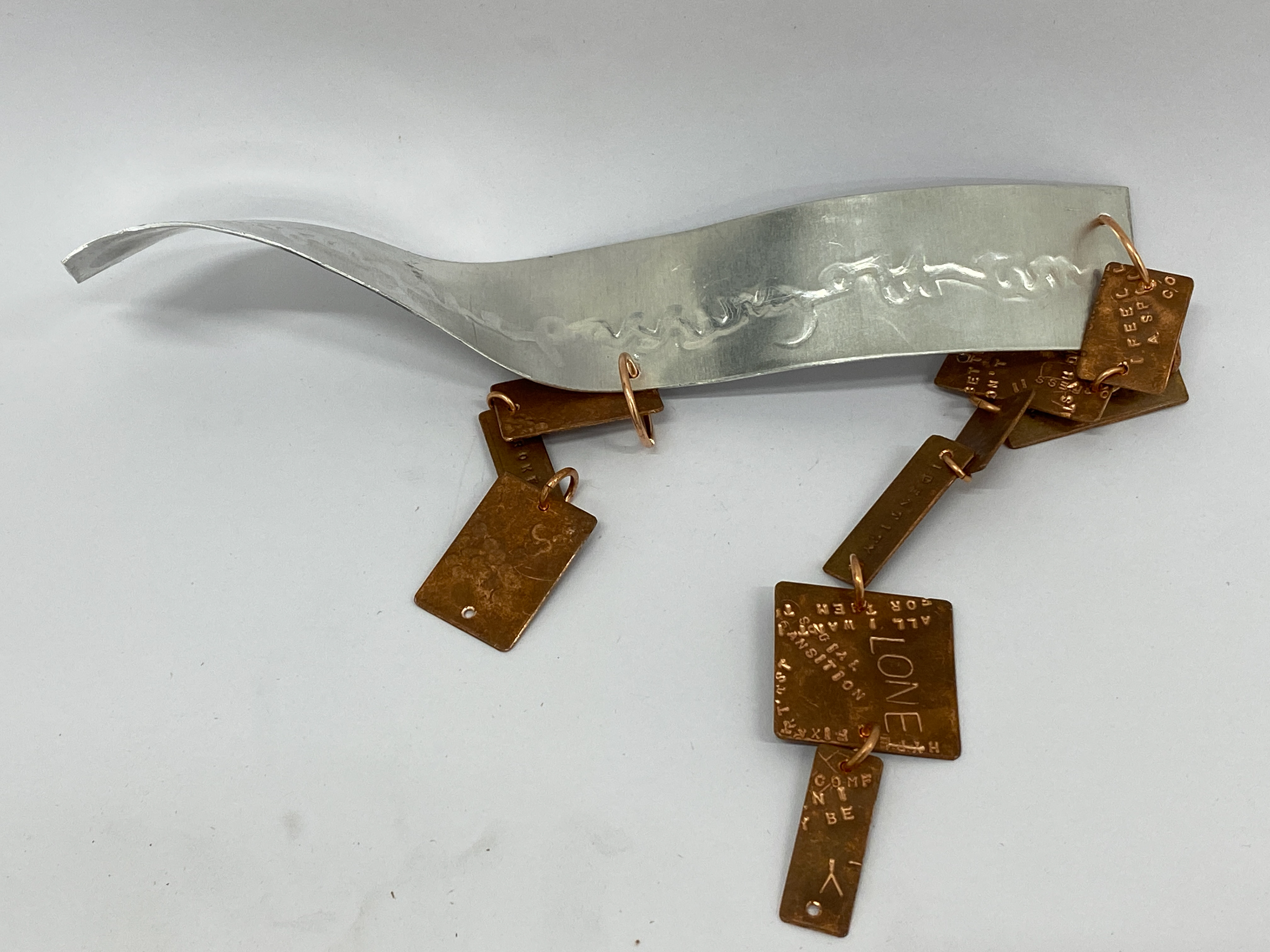

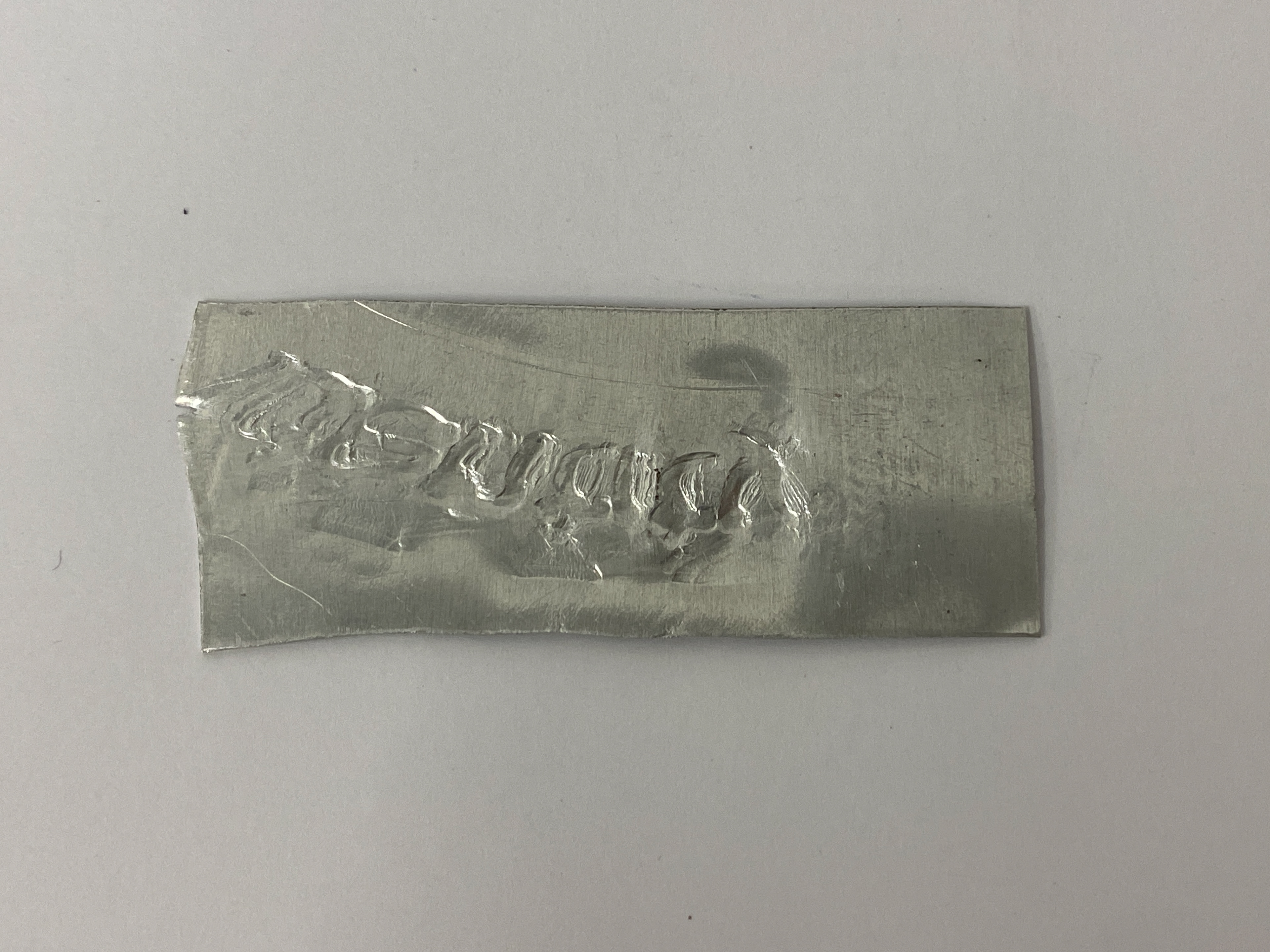

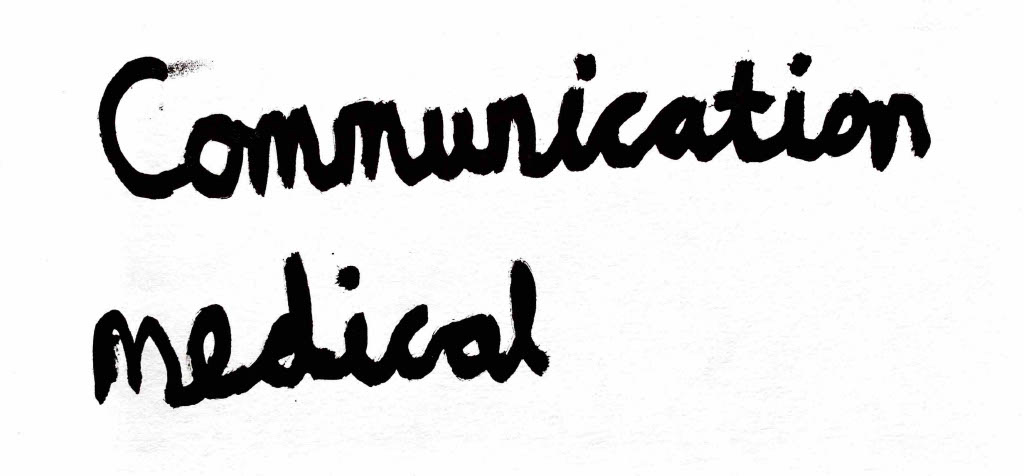

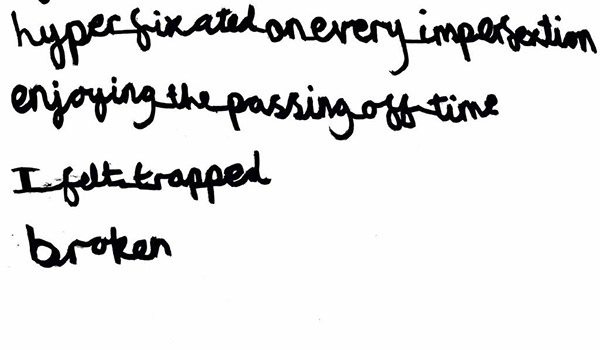

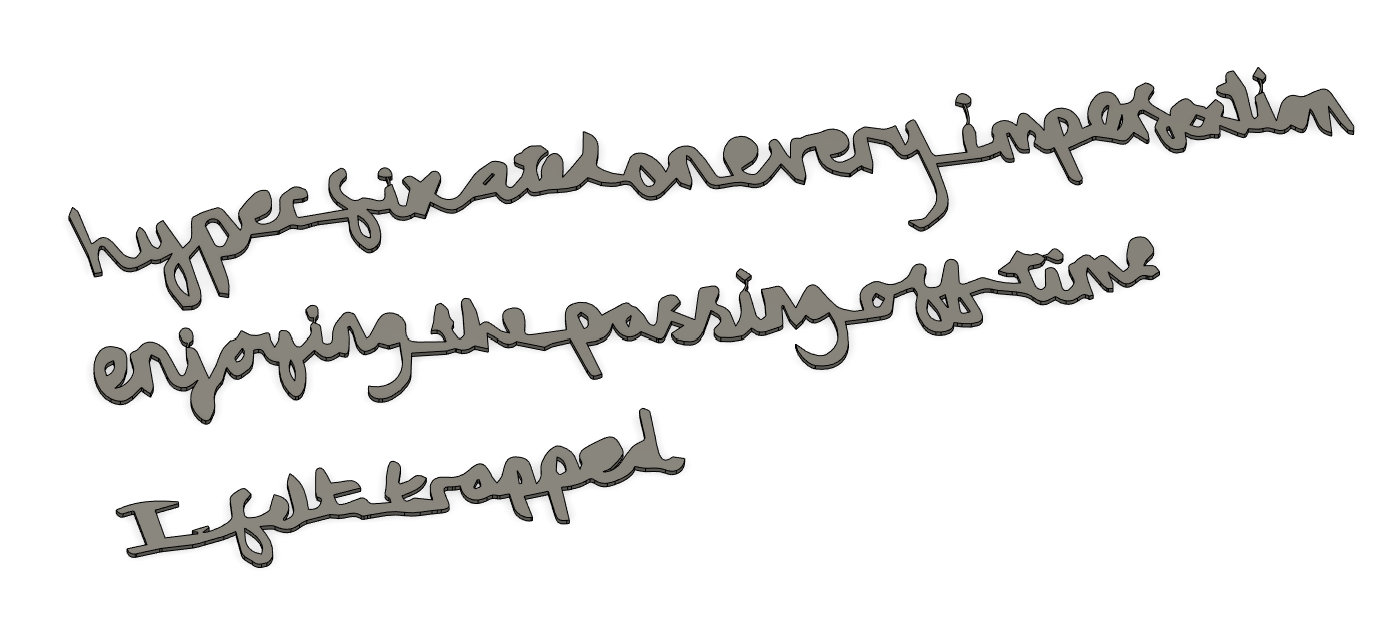

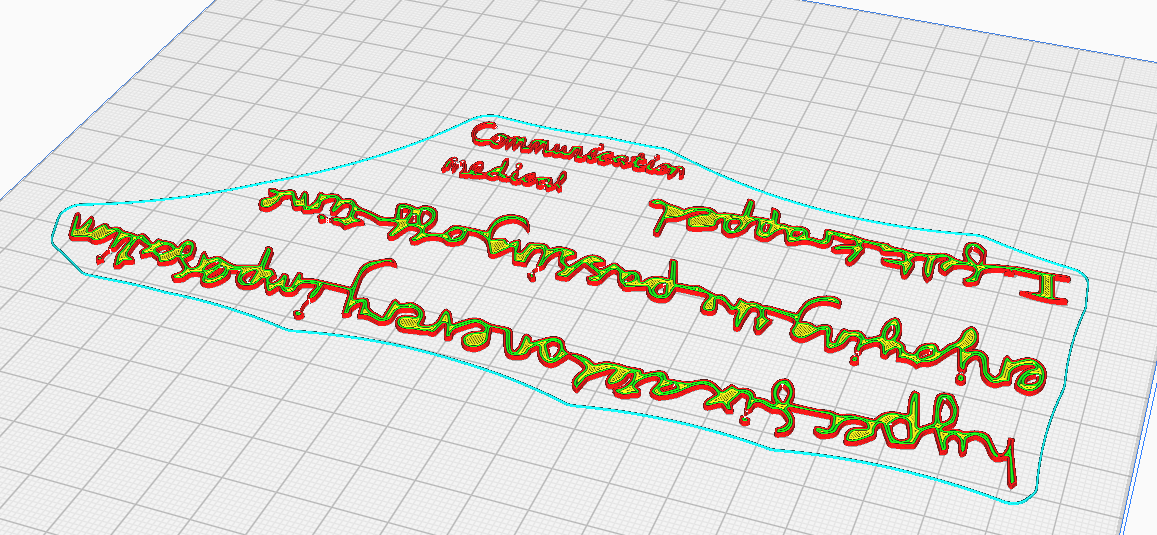

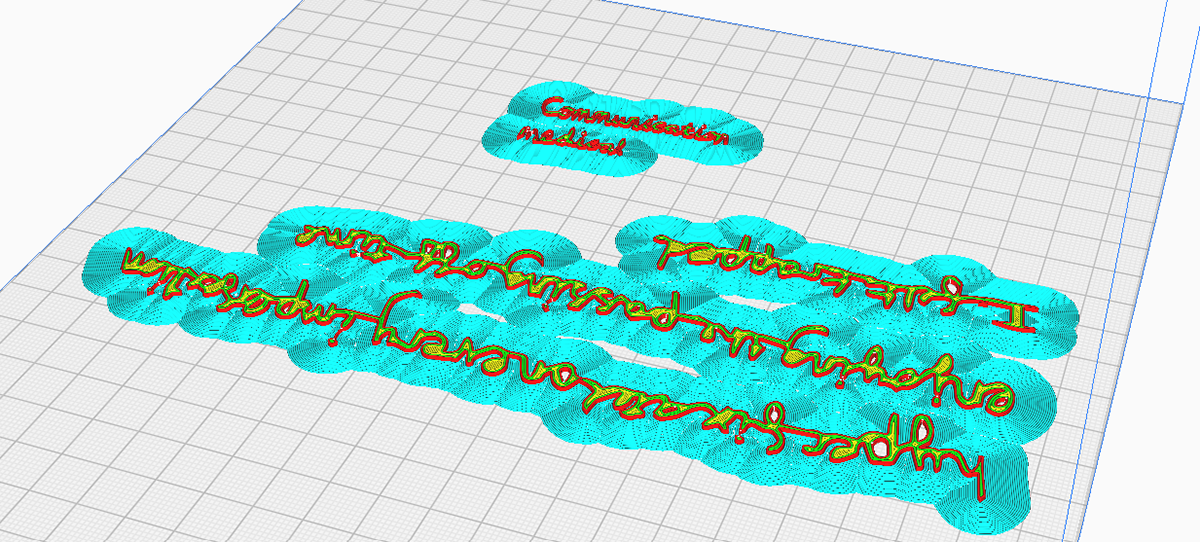

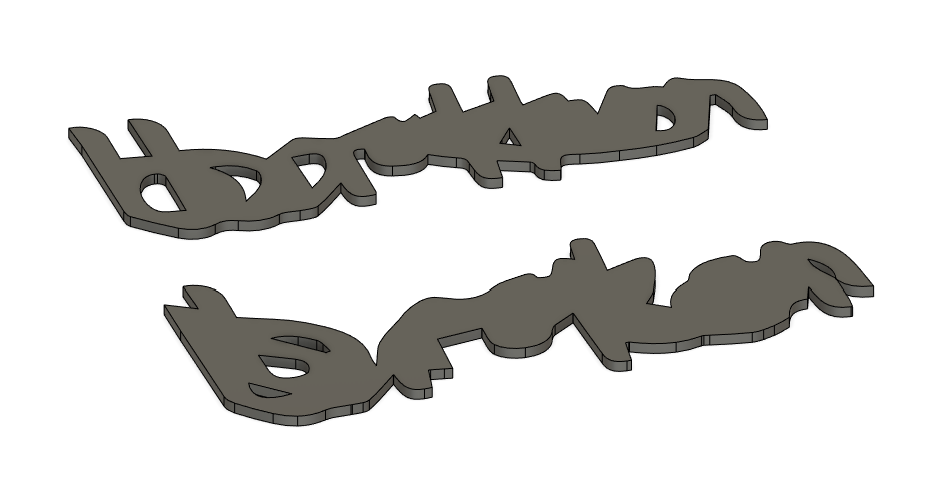

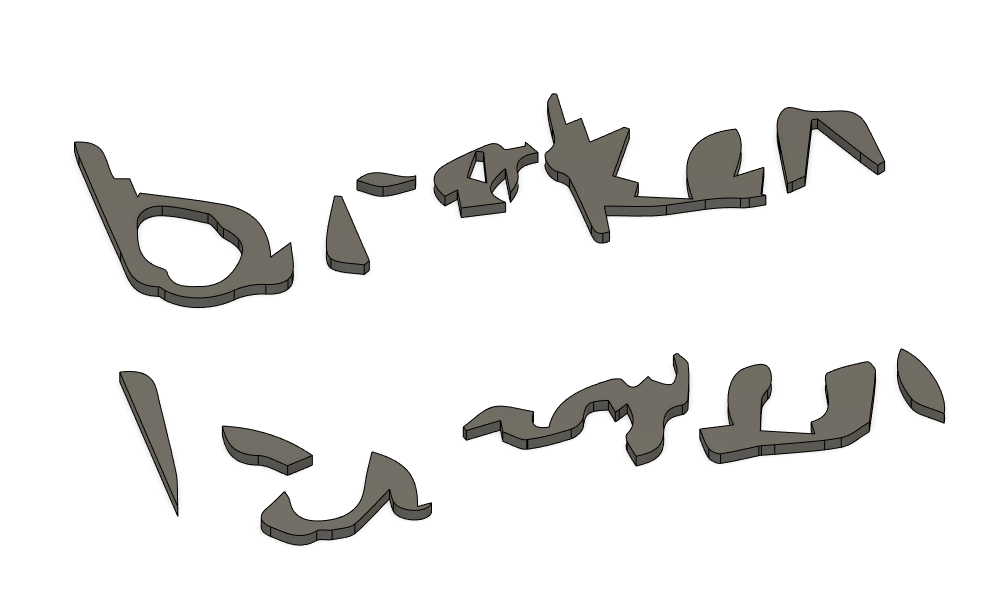

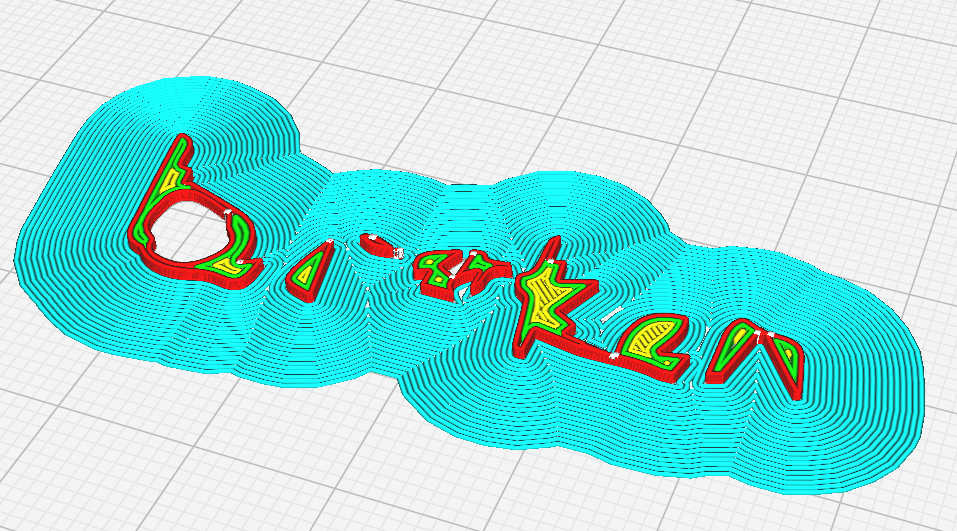

I found that the typed text felt void of personality and identity. Therefore, I tested writing out words and phrases from my personal diary on paper and scanned them into adobe to be converted to vectors which I used to create 1mm thick extrusions in Fusion 360. One of the main challenges was keeping the words and individual letters connected using small bridging lines so that all the components would stay aligned when passed through the roller.

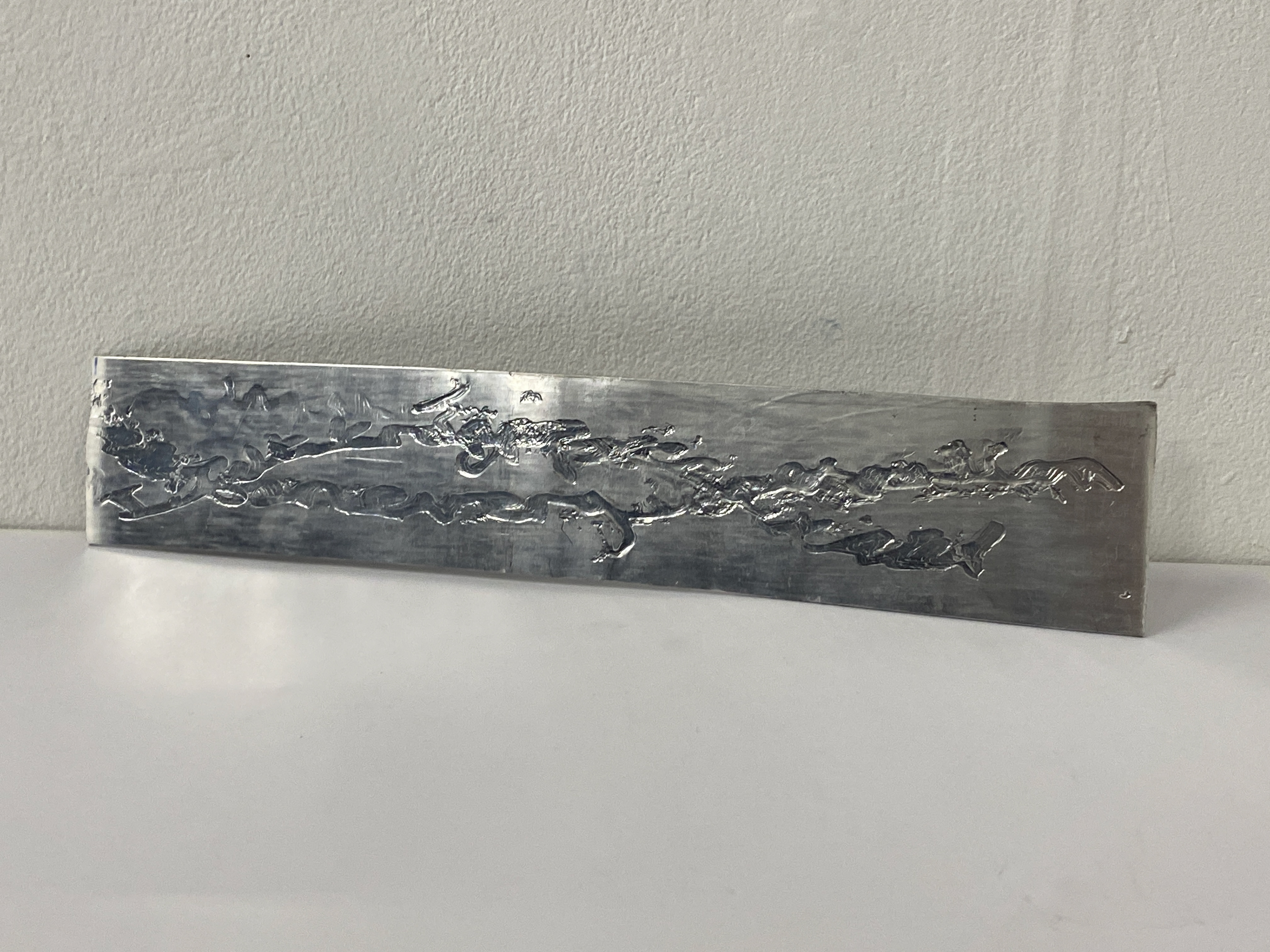

Differing the thicknesses of aluminium and amount of force applied by the rollers gave varying depth and clarity of the words. I found it hard to keep the smaller lengths of script in line and the thinner the aluminium sheet the more it tended to stretch in a curved direction out of parallel to the rollers. I also experimented with laying multiple lines of script over each other by passing the sheet back through the rollers with another length of text. This didn’t give the desired result as the second pass would flatten and distort the previous imprint. I want to experiment with this further but create a textured sheet where multiple phrases are included to roll them only once.

Reflecting on previous experiments I found that there are only limited ways that the rolling method distorts the text. Therefore, I imported the script into photoshop and layered the word on top shifting it and testing different layer overlay blending to break up or duplicate lines.

Unlike previous tests some of the digital distorted compositions relied upon the components of the word not connecting. Therefore, I experimented with using brims which traditionally help with adhesion of larger prints to the print bed, but in this instance, I used them to create a 1-layer thick plate that connected all the components together. This also helped with alignment when passing through the roller as it gave me greater surface area to grip onto. However, this did also affect the visual outcome as the cylindrical layer patten from the printer head was passed onto the surface of the aluminium by the rollers.

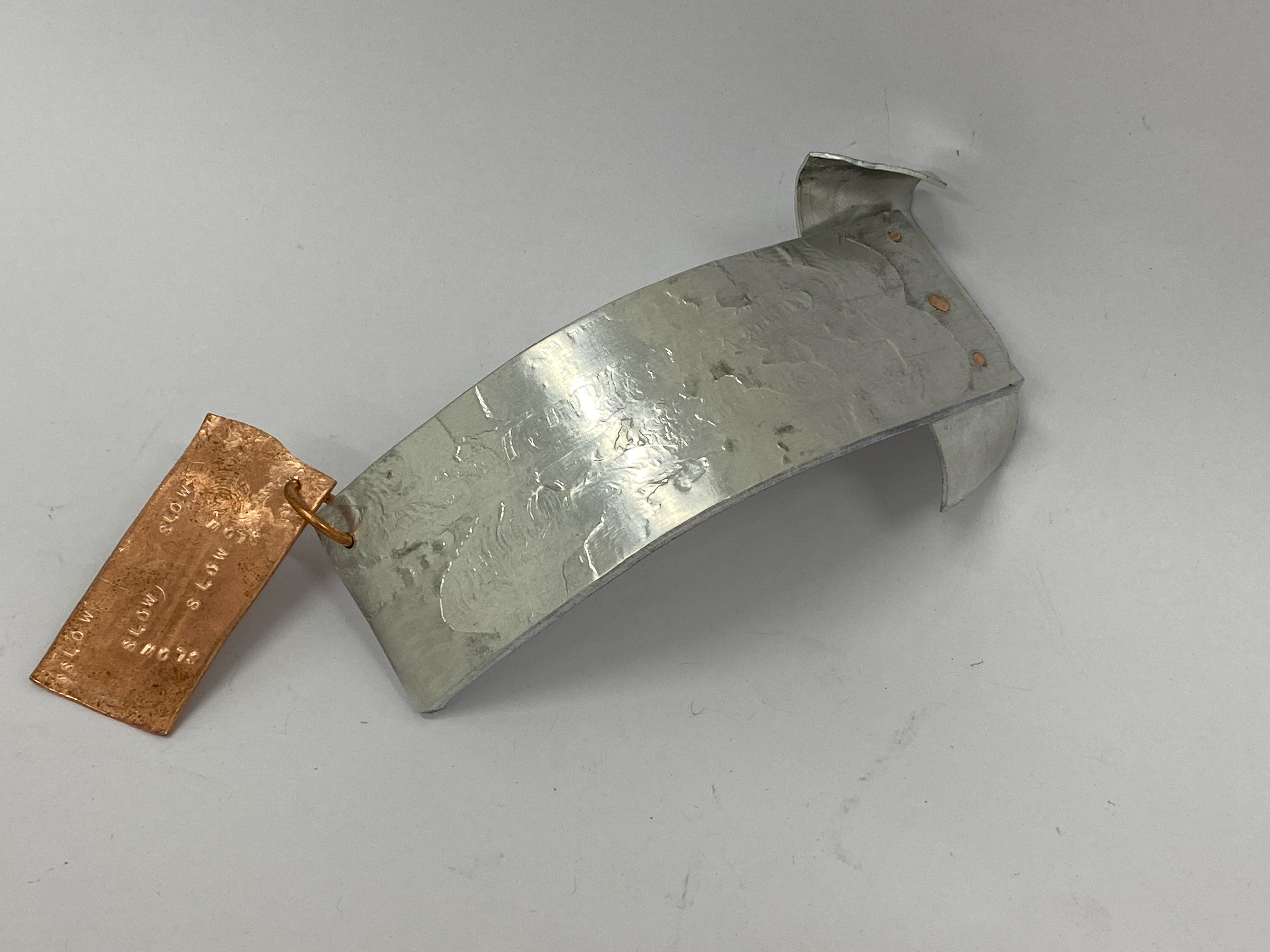

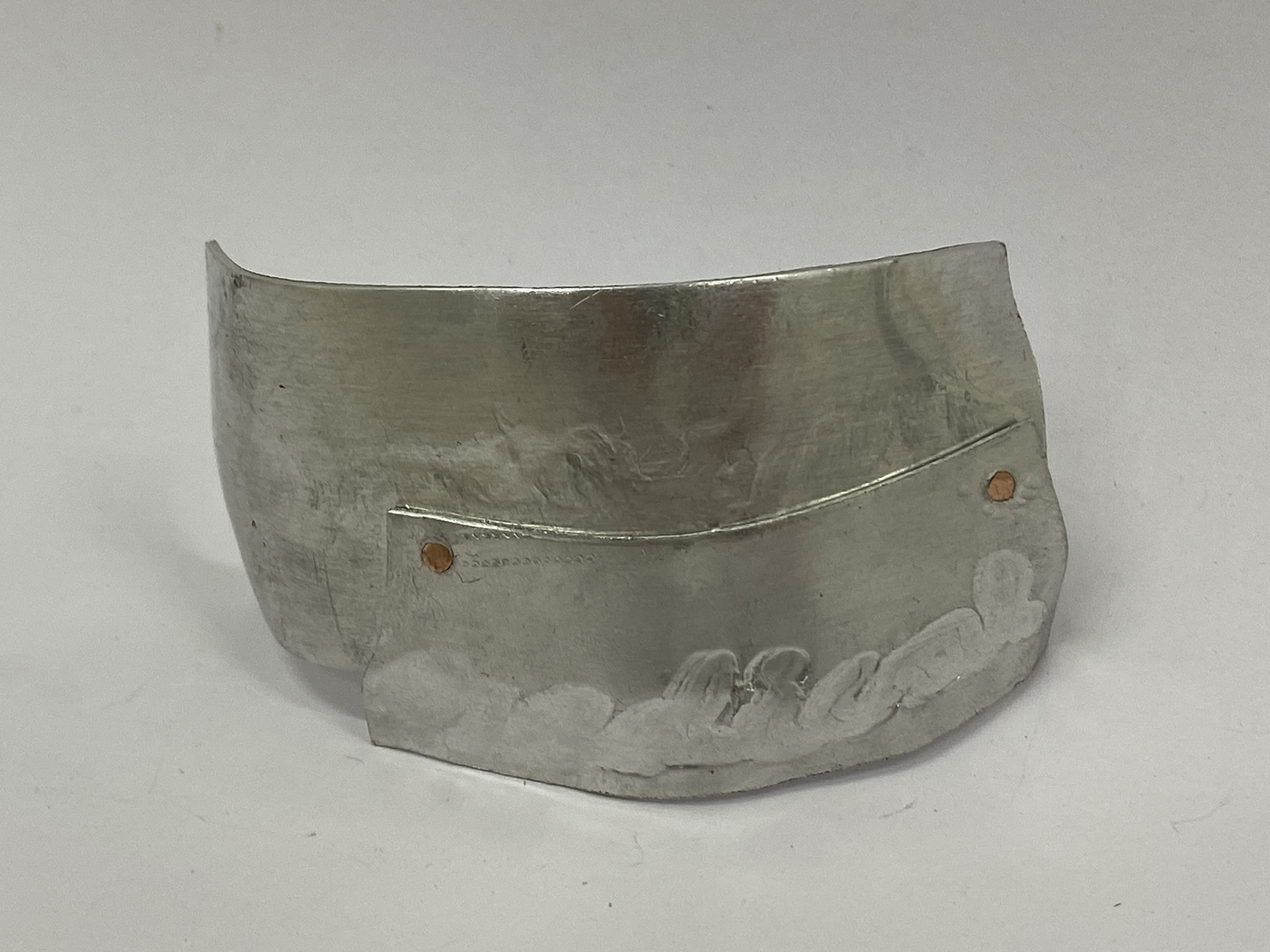

Initially I saw the sacrificial textured plates only uses was for the rolling process. However, reflecting on their changed form I found them to not only be visually striking but also, they tell the history of the making process through their distortion. I want to place them alongside the rolled metal in the same piece to give a glimpse into how the differing layers of censorship through distortion was created.

Investigating different ways to attach the PLA 3D prints to metal sheet using rivets and jump rings inspired by my trip to Leeds Armoury.

These are some of my tests to experiment with creating 3D forms that could lie on the shoulder. I wanted to experiment further with riveting to create fixed joints and jump rings to create movement. I would like to take traditional techniques of connecting and joining armour to create a modern wearable piece that investigates protection from emotion rather than physical blows.