Cost of tooling

Most of the tools I used are from the University workshop and others that I have in my own collection. However, I did purchase a leather punch to improve the quality of the holes in my leather working.

Leather punch = £5

Material Costing

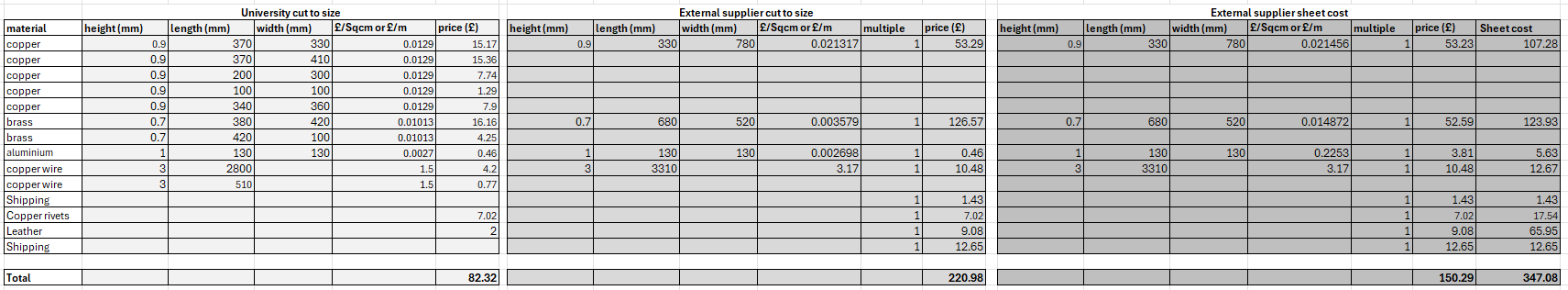

Exploring the costing of sourcing materials from different locations:

Material cost using University source

Purchasing material through the University is a system where you only buy the size needed and the price is calculated by pounds per square centimetre for sheet, and pounds per metre for wire. The University purchases all material in bulk lowering their cost compared to any external provider.

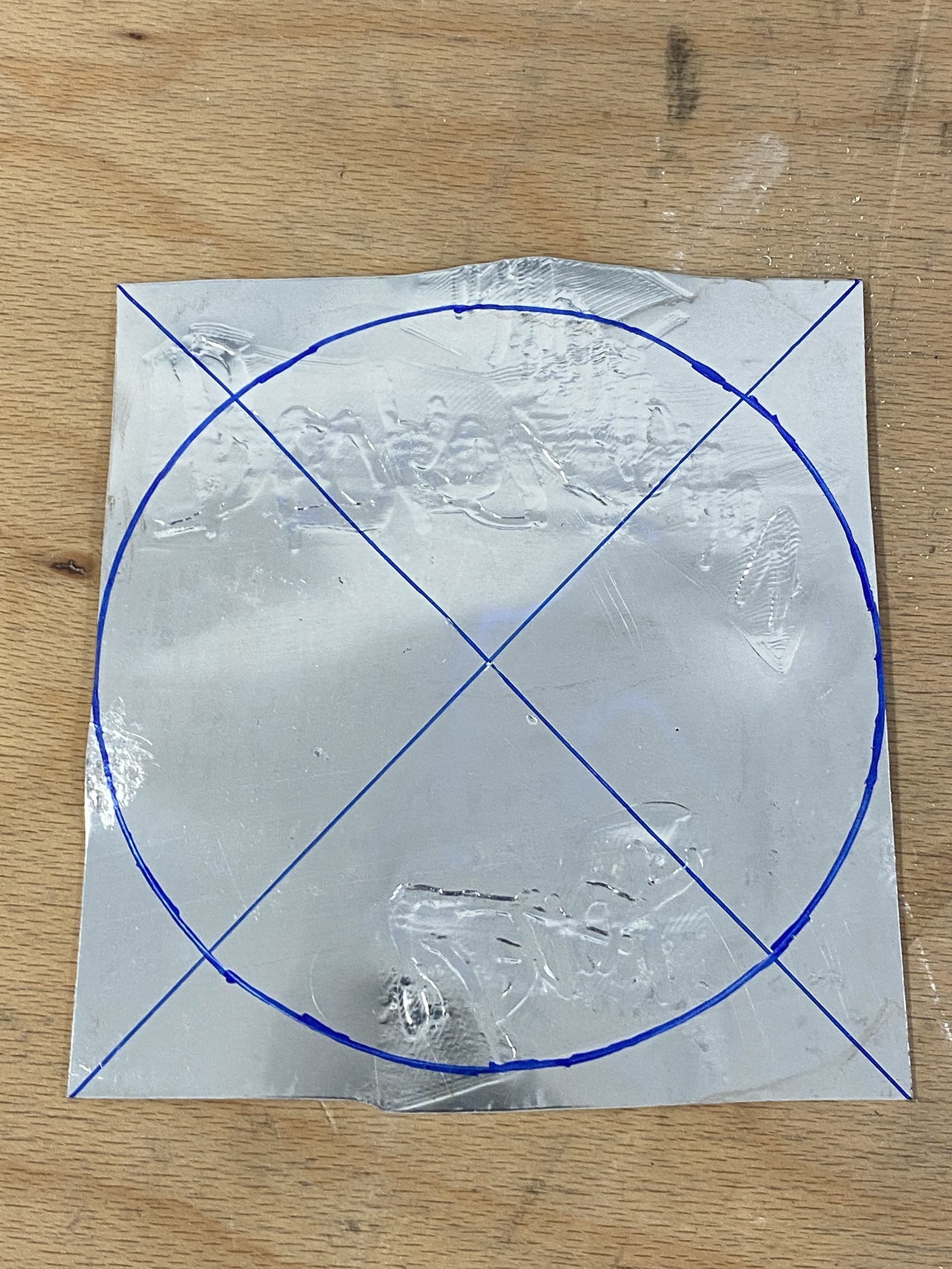

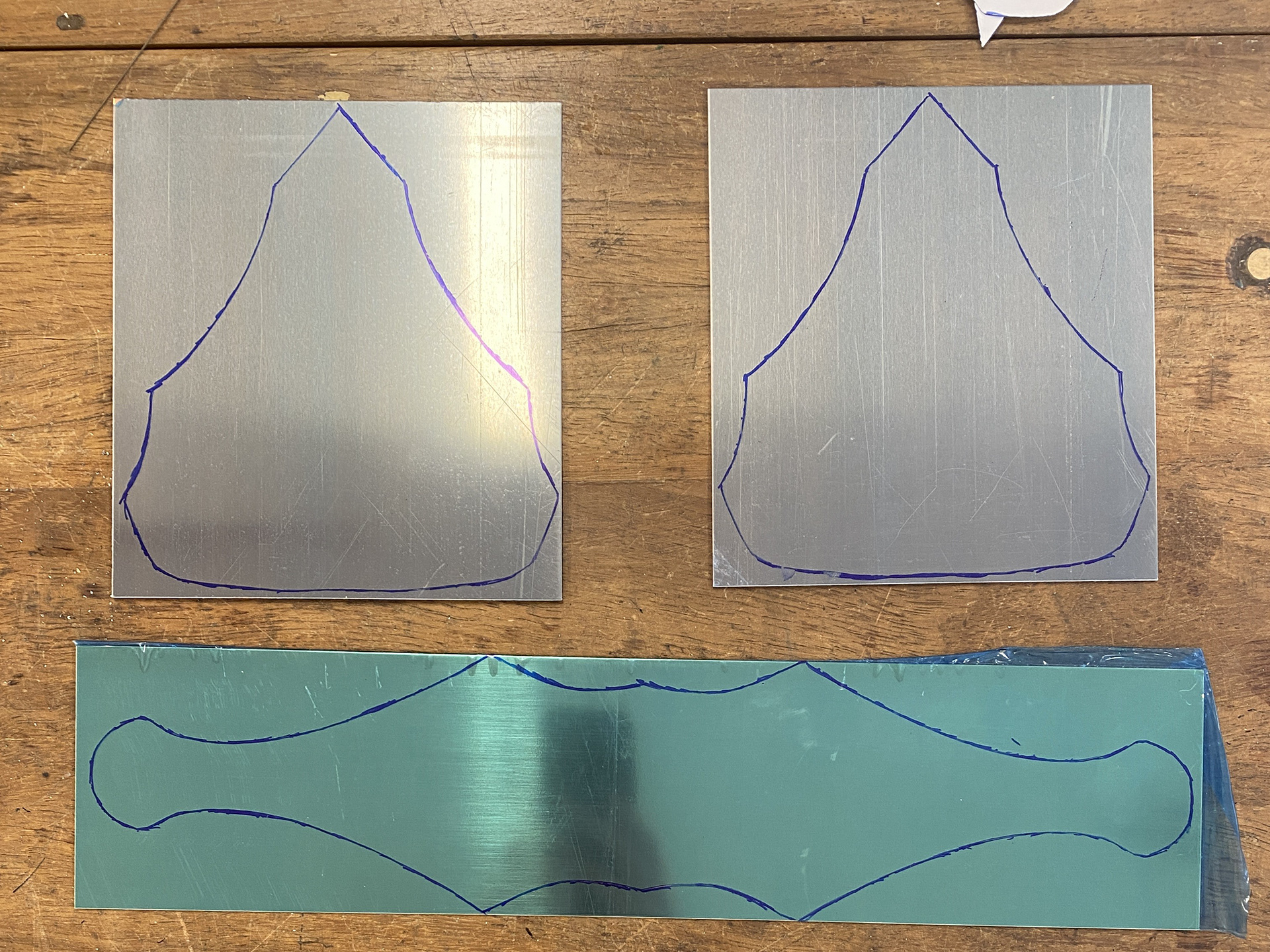

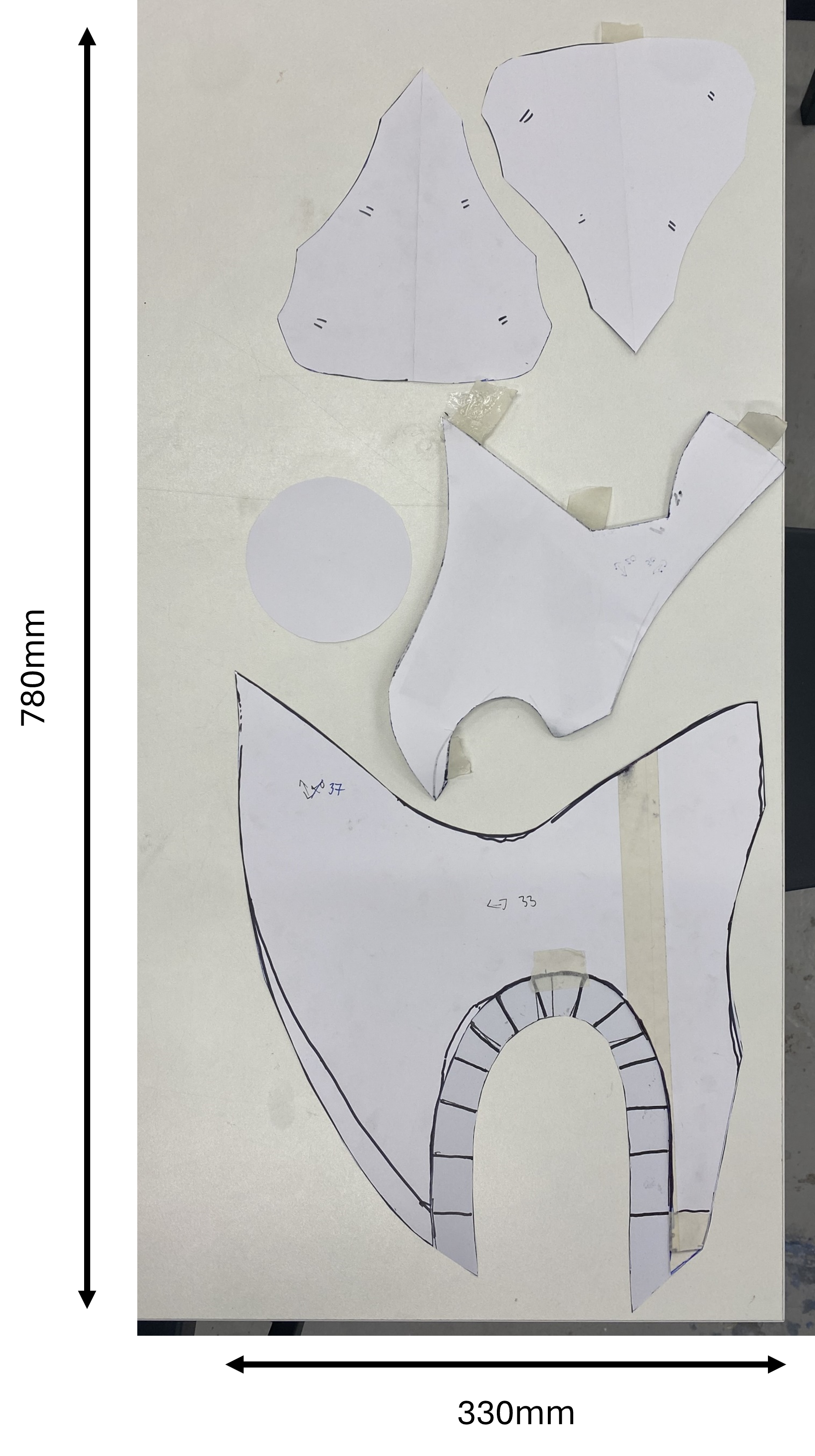

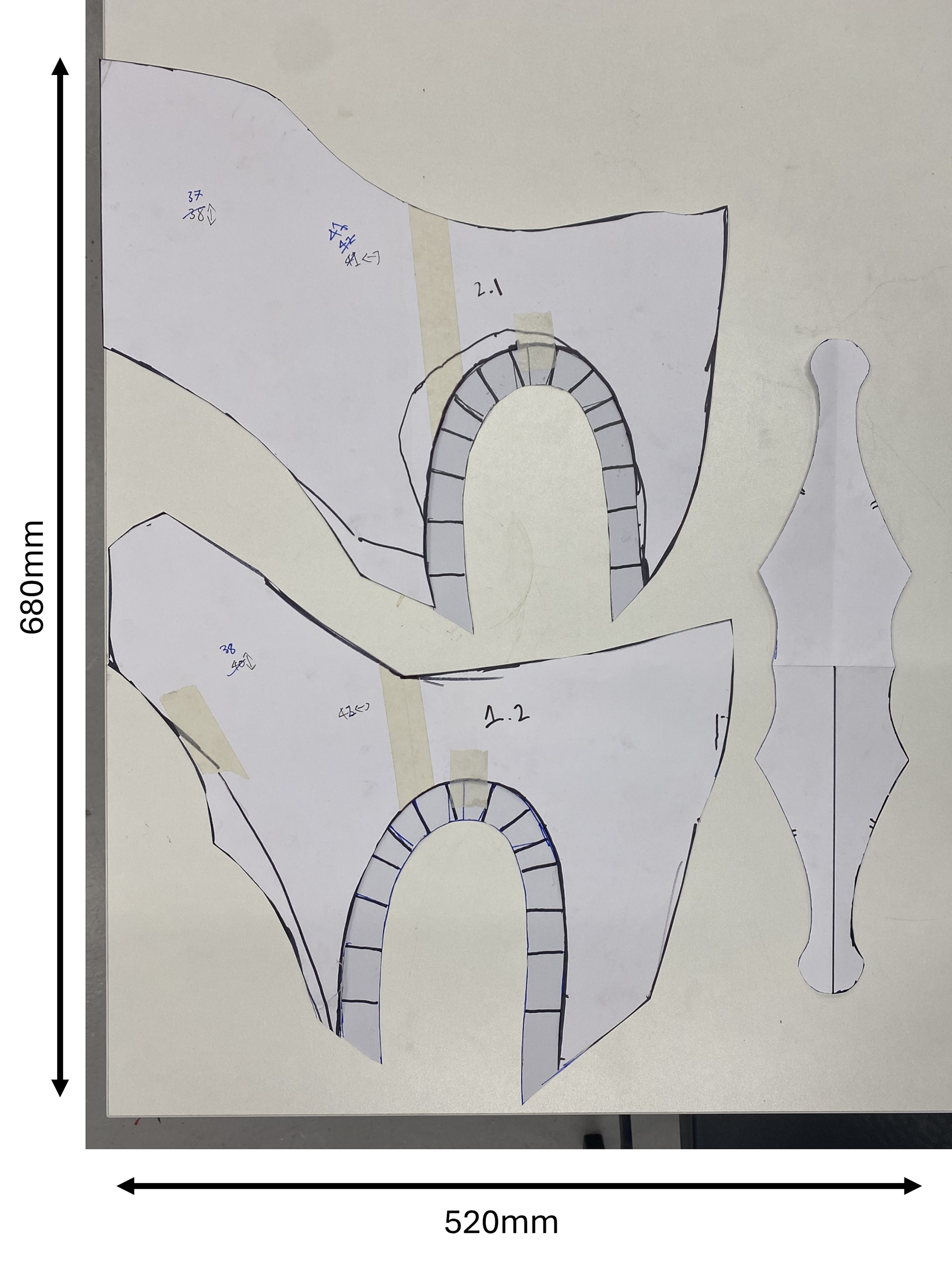

I purchased each components' material separately, as all the sizes of sheet were suitable to be cut using only the bandsaw. If I purchased a larger sheet with all the shapes tessellated, I would have needed to roughly cut the shapes using a pair of hand shears to break an overall sheet down into individual components. I compared the price of each method and found that it was only a couple of pounds between each and the additional work to cut up a larger sheet was not worth my time. Moreover, cutting the large sheet up would create lots of sharp edges and distort the material making it harder to accurately pass through the bandsaw.

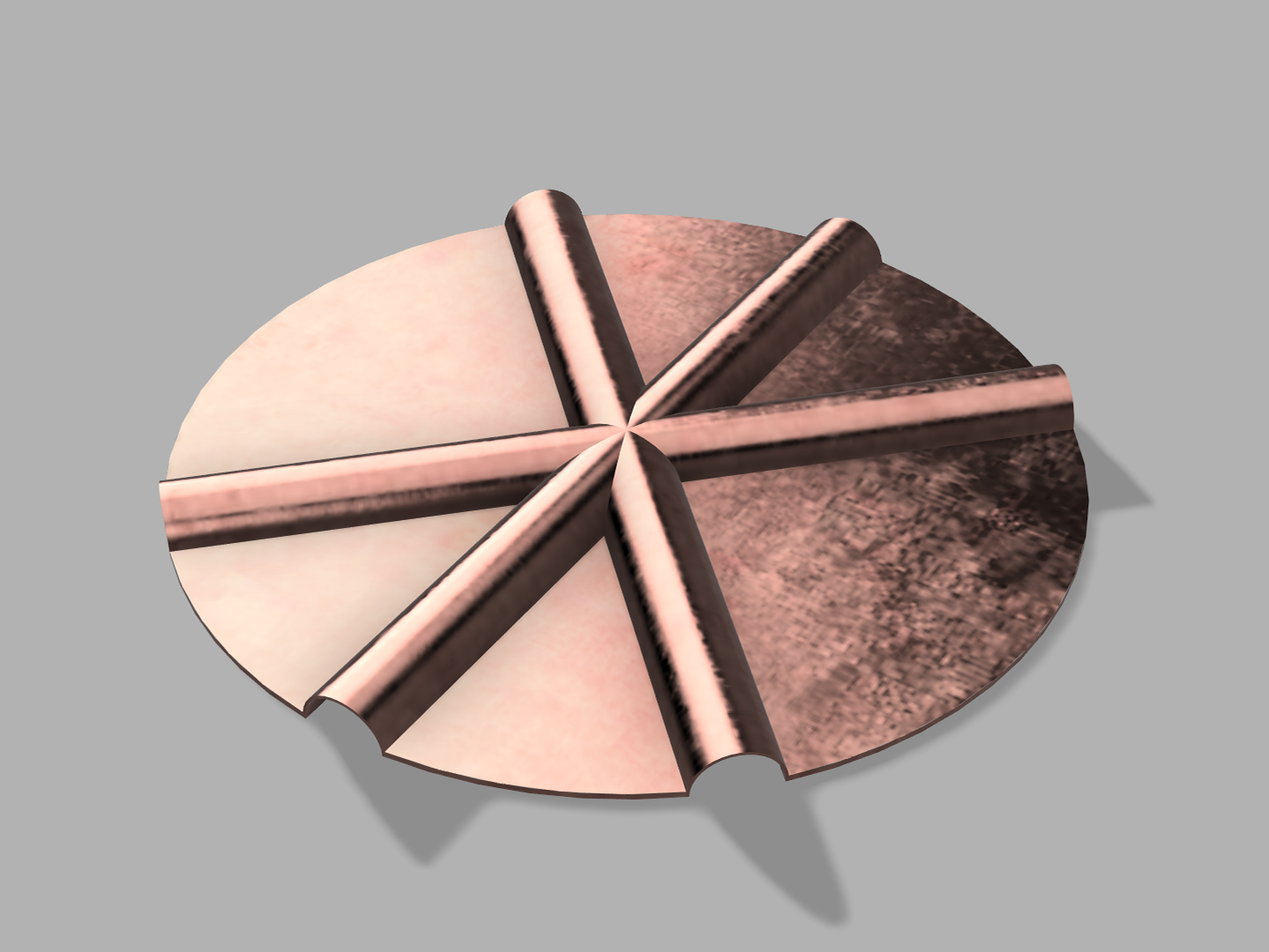

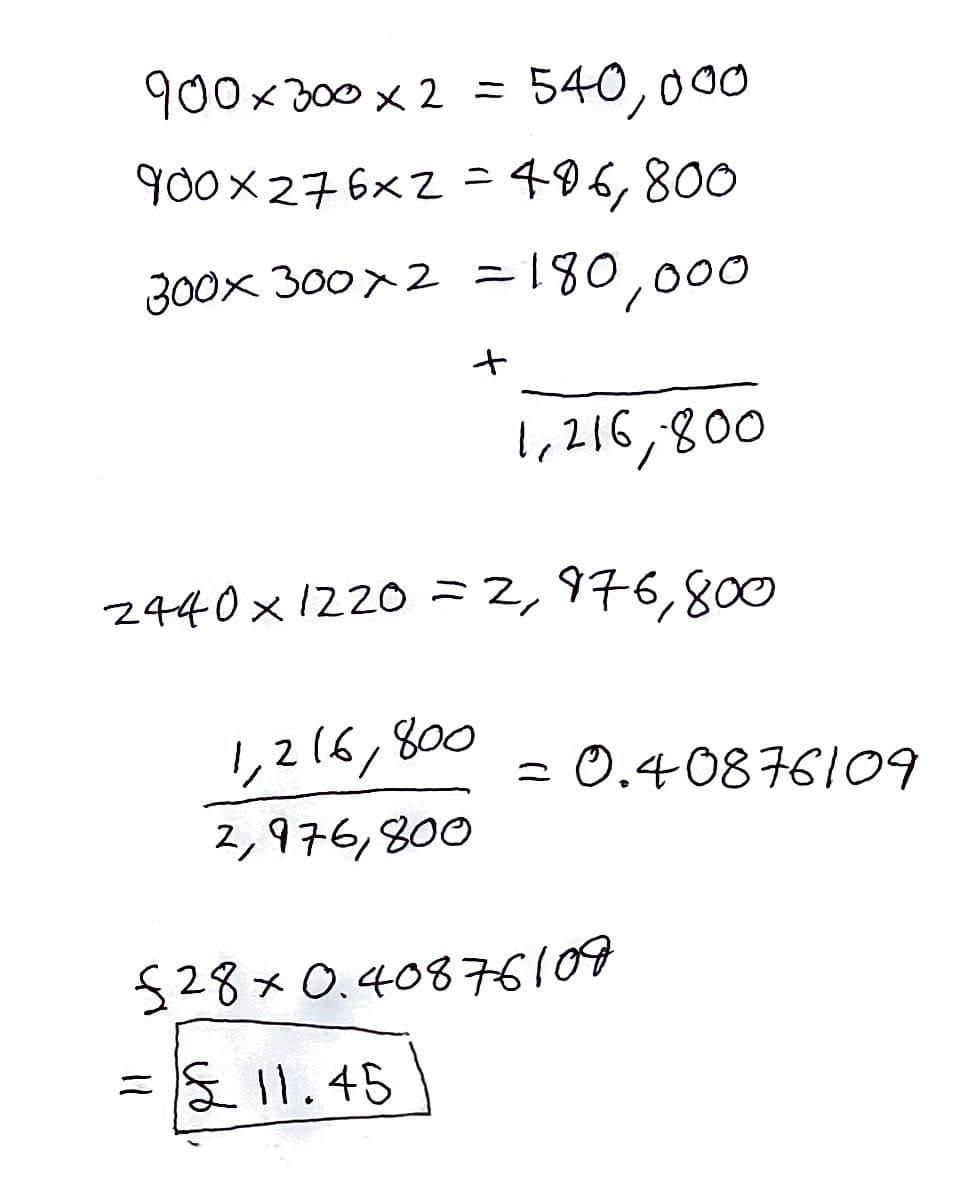

Example of costing using the University as a source for the Elbow section:

I purchased each sheet separately which assembles to create the whole component

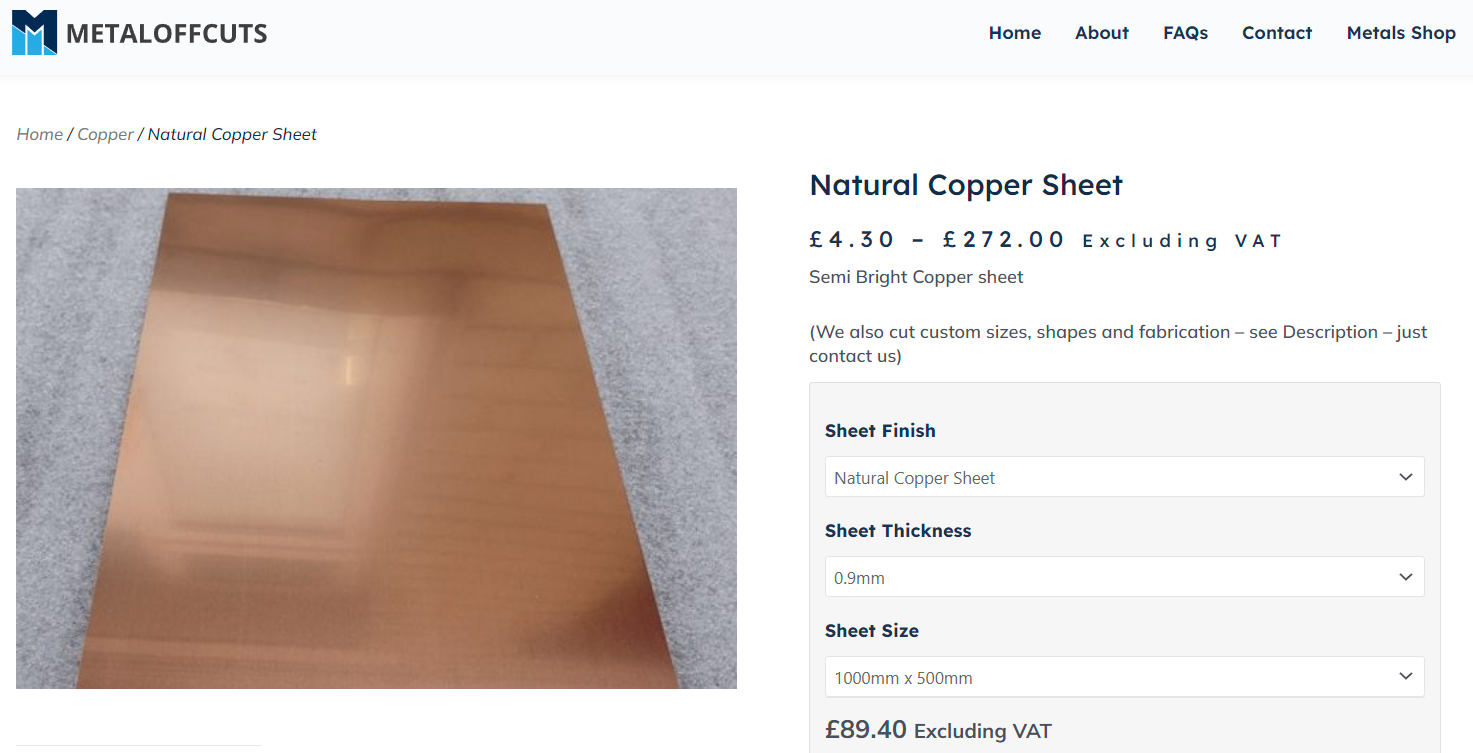

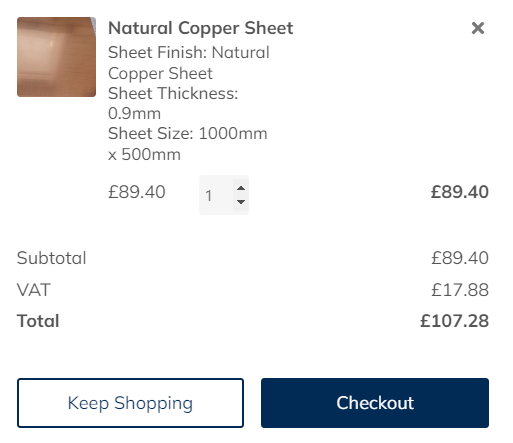

0.9x170x180mm copper = £3.95 x 2 = £7.90 (£/Sqcm = 0.01290)

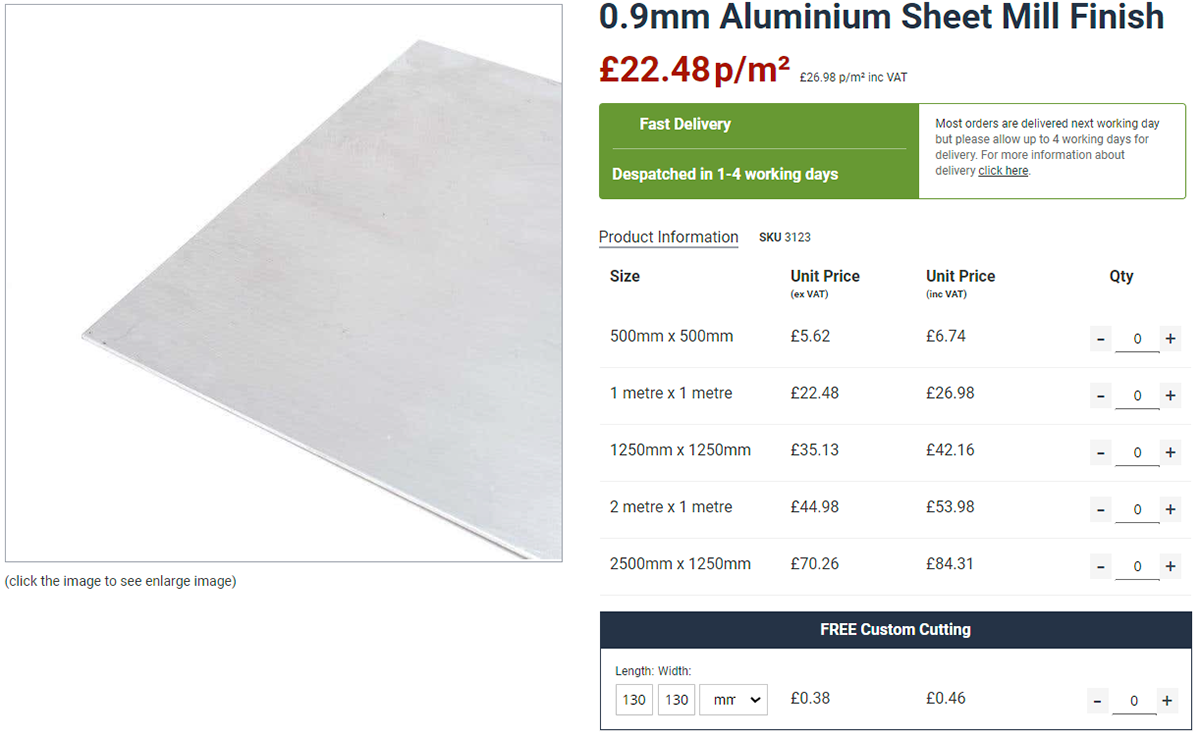

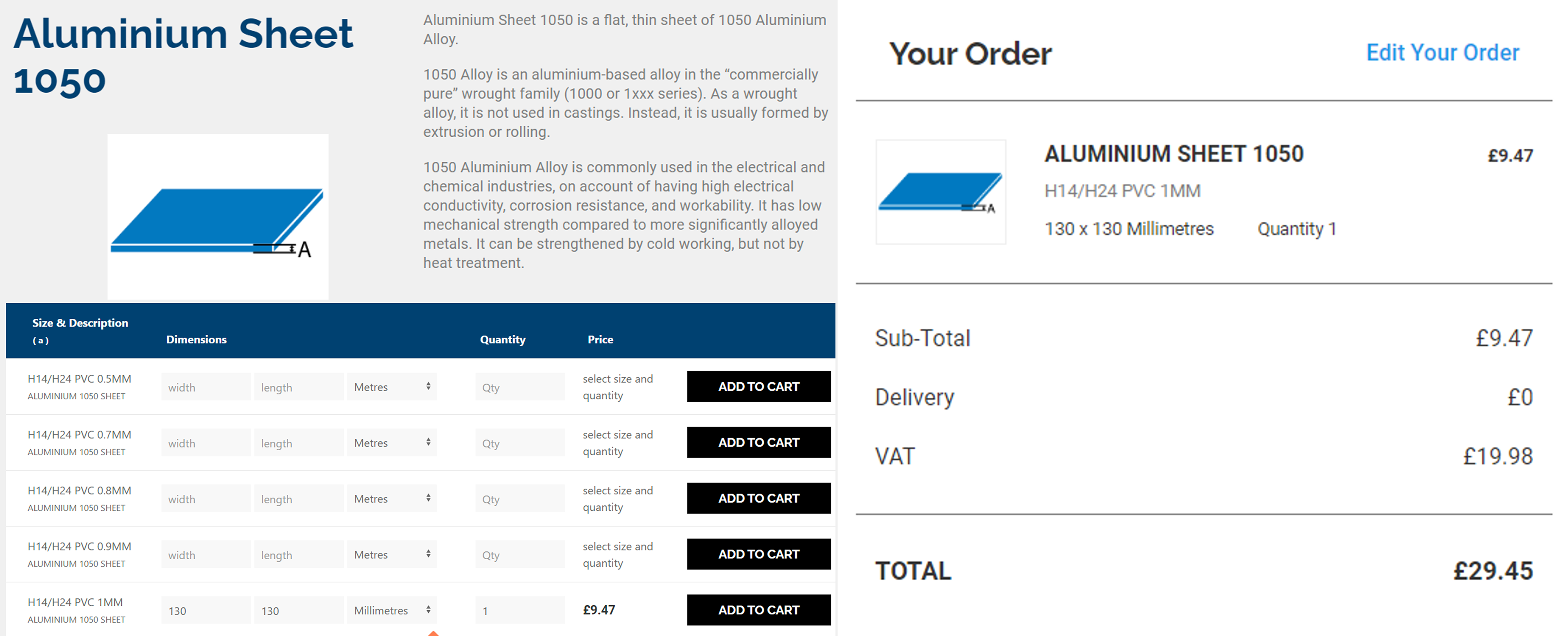

1.0x130x130mm aluminium = £0.46 (£/Sqcm = 0.00270)

0.7x420x100mm brass = £4.25 (£/Sqcm = 0.01013)

The total cost of sheet for the Elbow section = £12.61

Some materials I had to source from outside the University as it isn’t stocked.

The most cost-effective way to source the paint to finish the plinth was through amazon. I only used half of each tin and therefore, added half the cost to my pricing spreadsheet. The rest can be used for future projects.

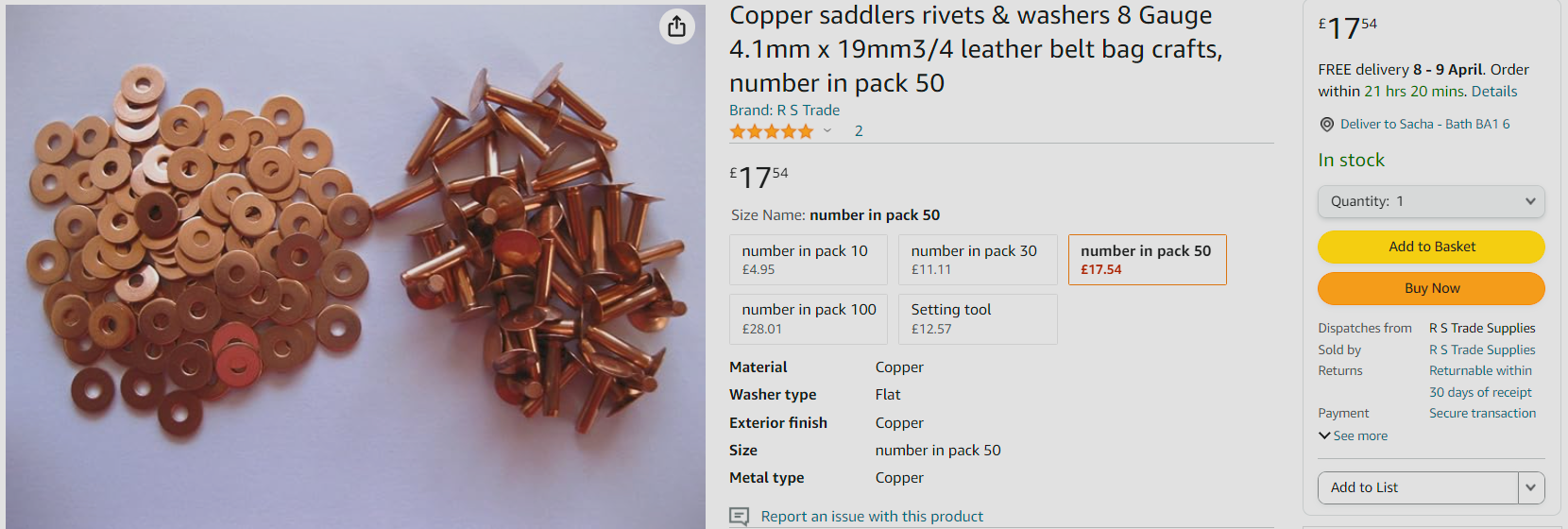

Copper rivets to attatch the leather to the sheet metal = £17.54 but I only used 20 which = £7.02 and the rest I will used for future projects.

I sourced the leather from Wiltshire Scrapstore who sell a variety of reclaimed off cuts from industry. I played £10 for a large bag for life of scraps varying in size and colour that I hand selected. I will only use a small portion of this, so I have costed the leather used at £2.

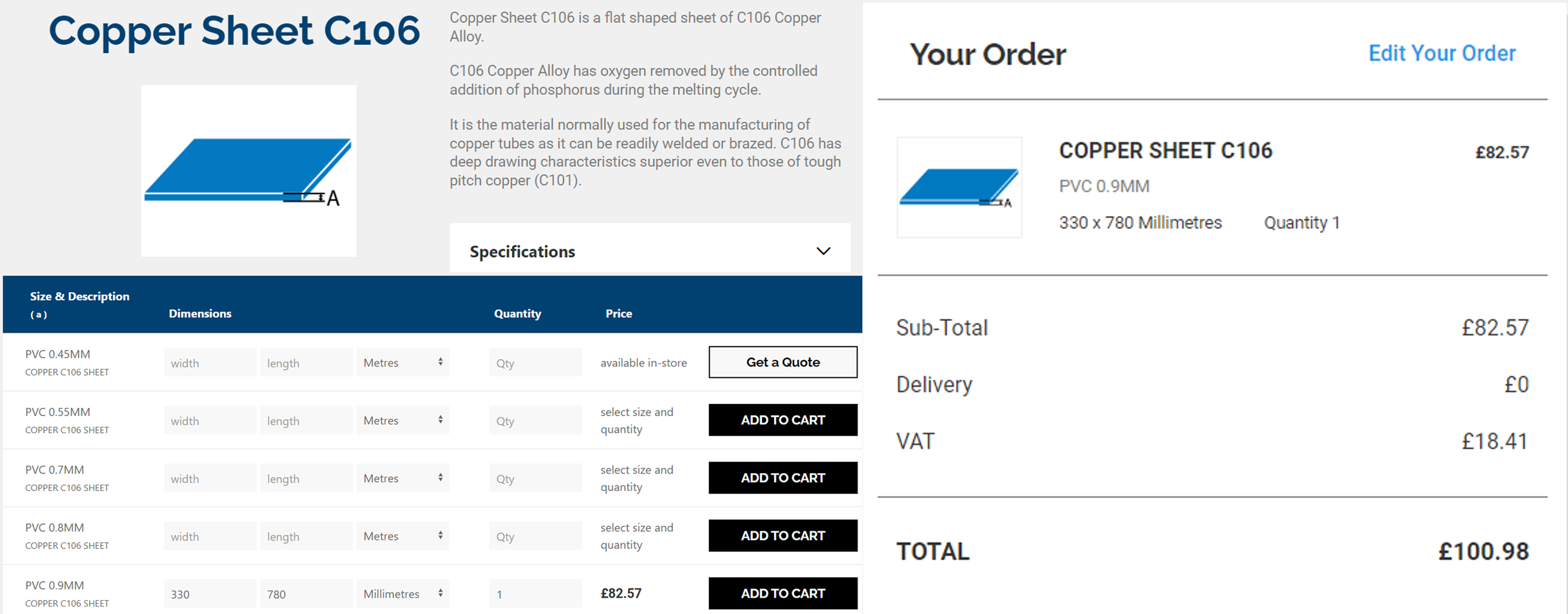

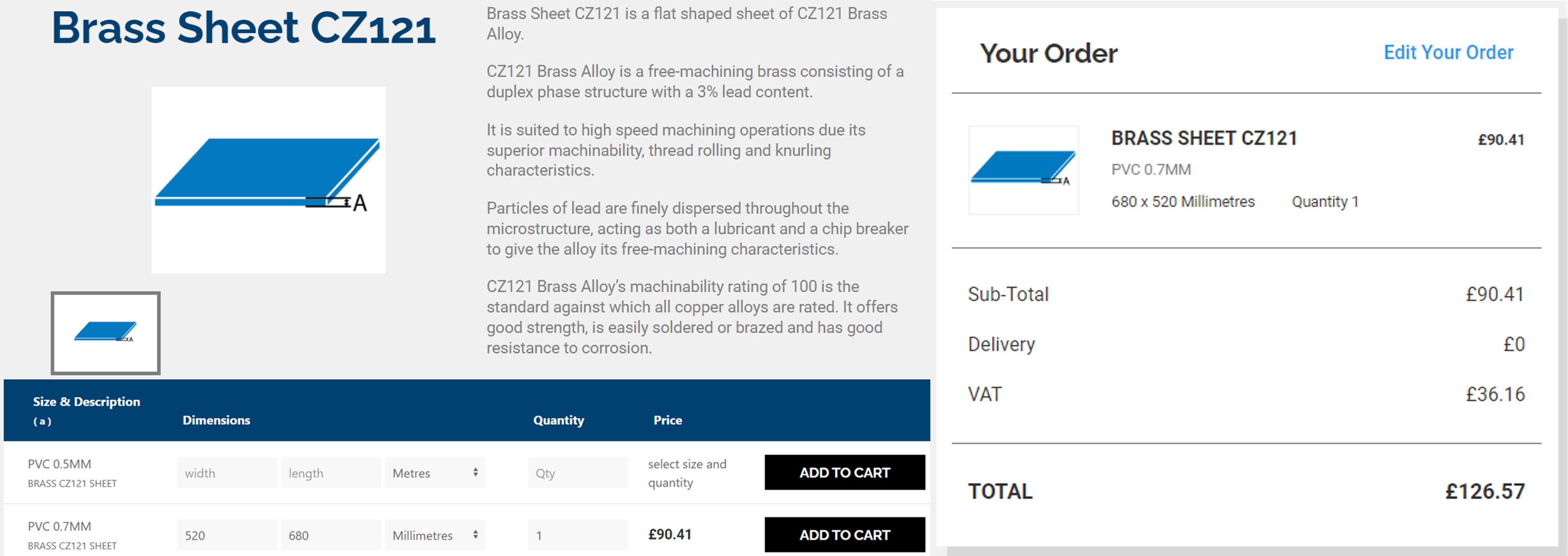

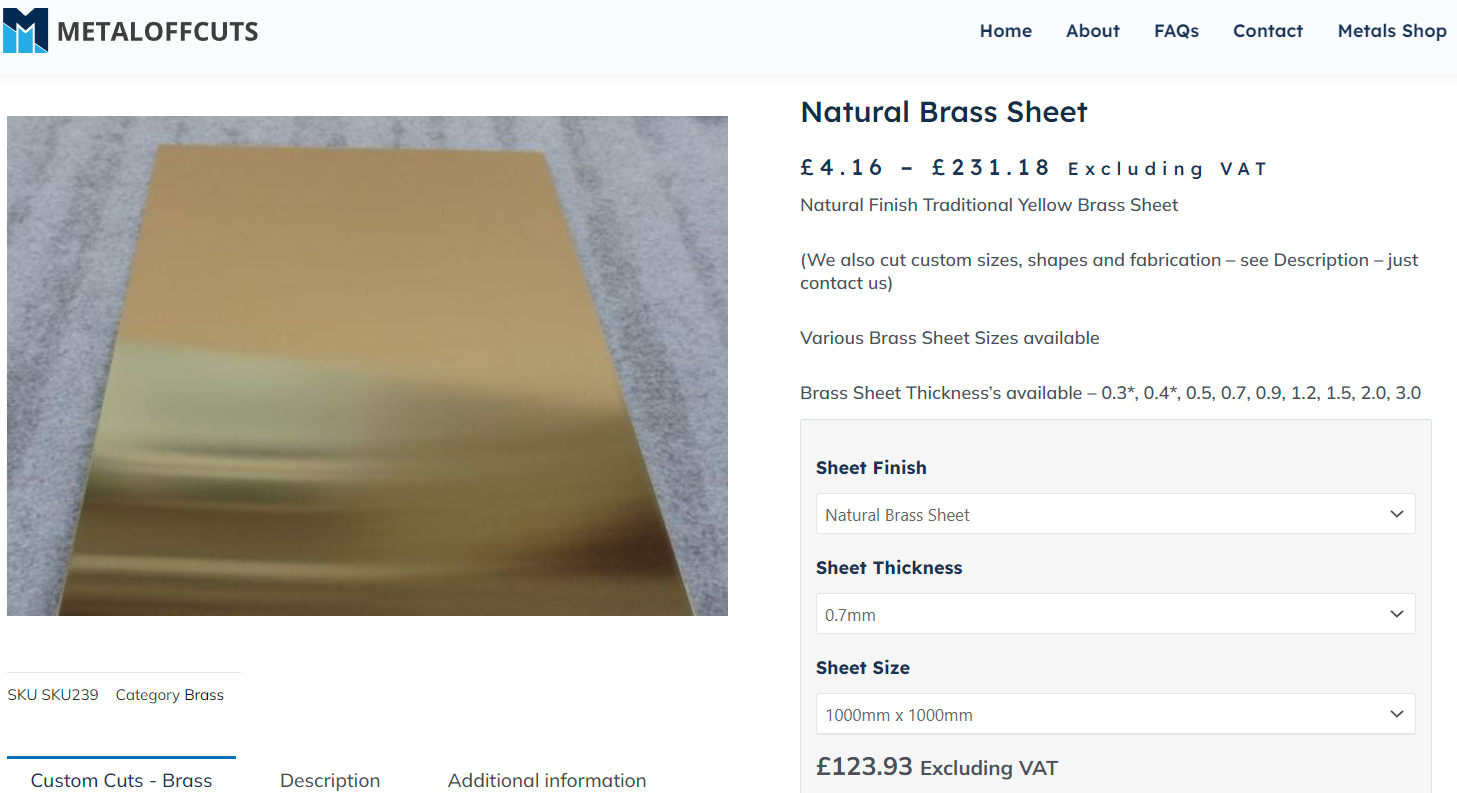

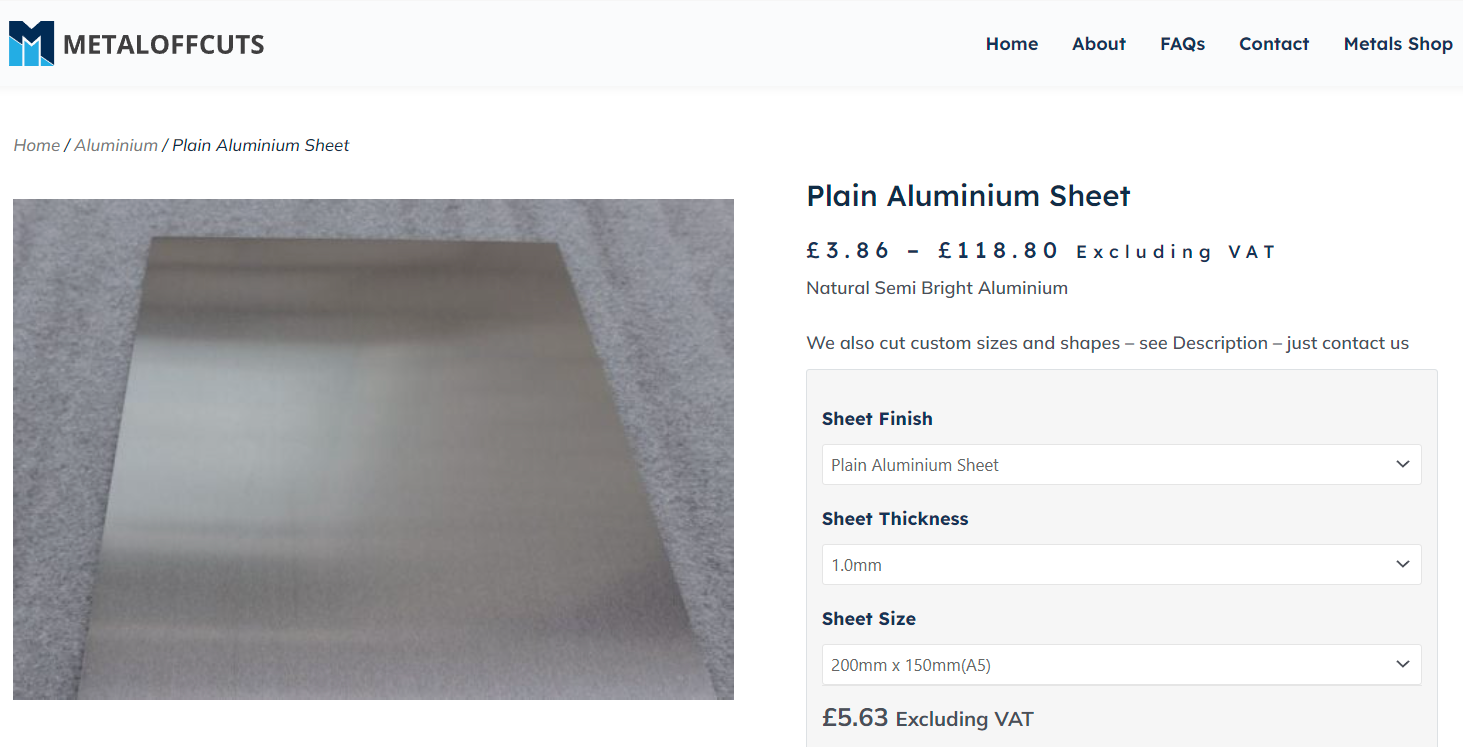

Material costs using externald providers cut to size

I looked through for a variety of sites that cuts sheet to custom size. This is the closest way to replicate purchasing the exact quantity of material needed through the University system. There was a lack of sites that could cut sheets with the large width and length with such a thin depth required. For example, I have used the same thickness of sheet when pricing comparatively, but using a 0.9mm instead of a 0.7mm brass would reduce the cost by £53.06. This would be something that I would need to consider when designing outside of university and work with the materials I will have available to me at a reasonable price.

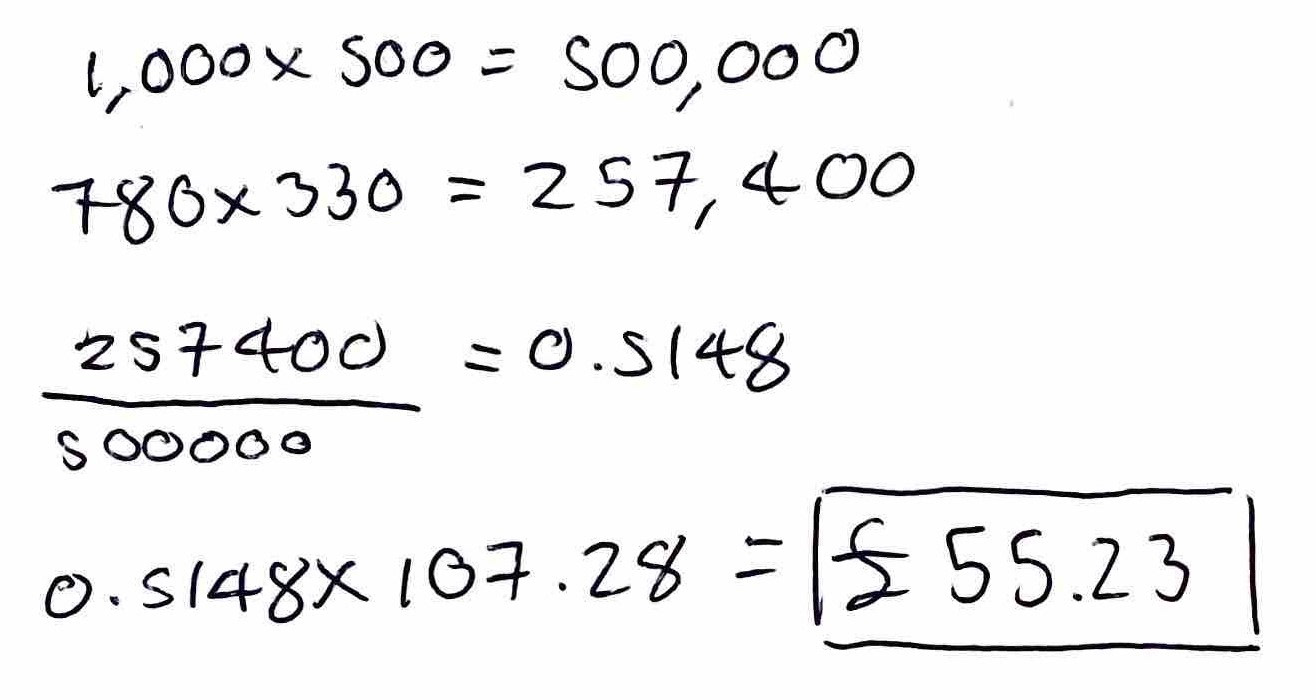

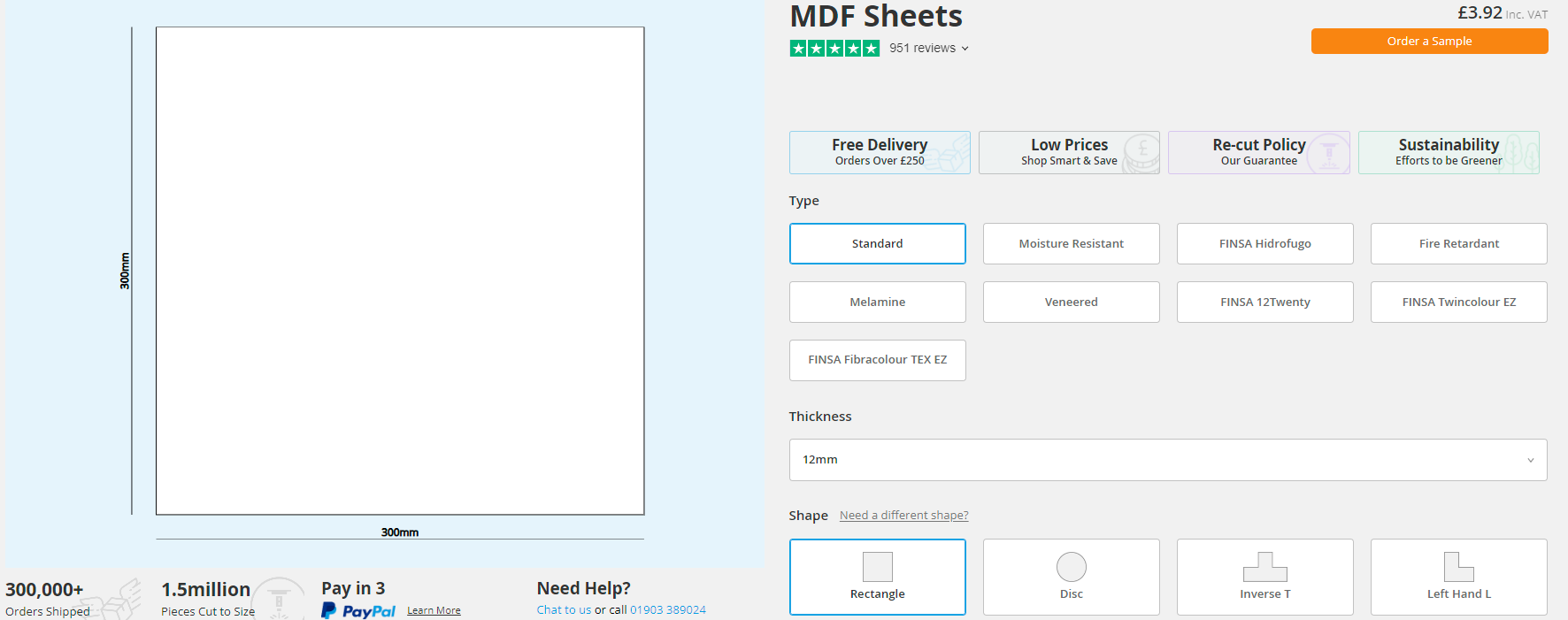

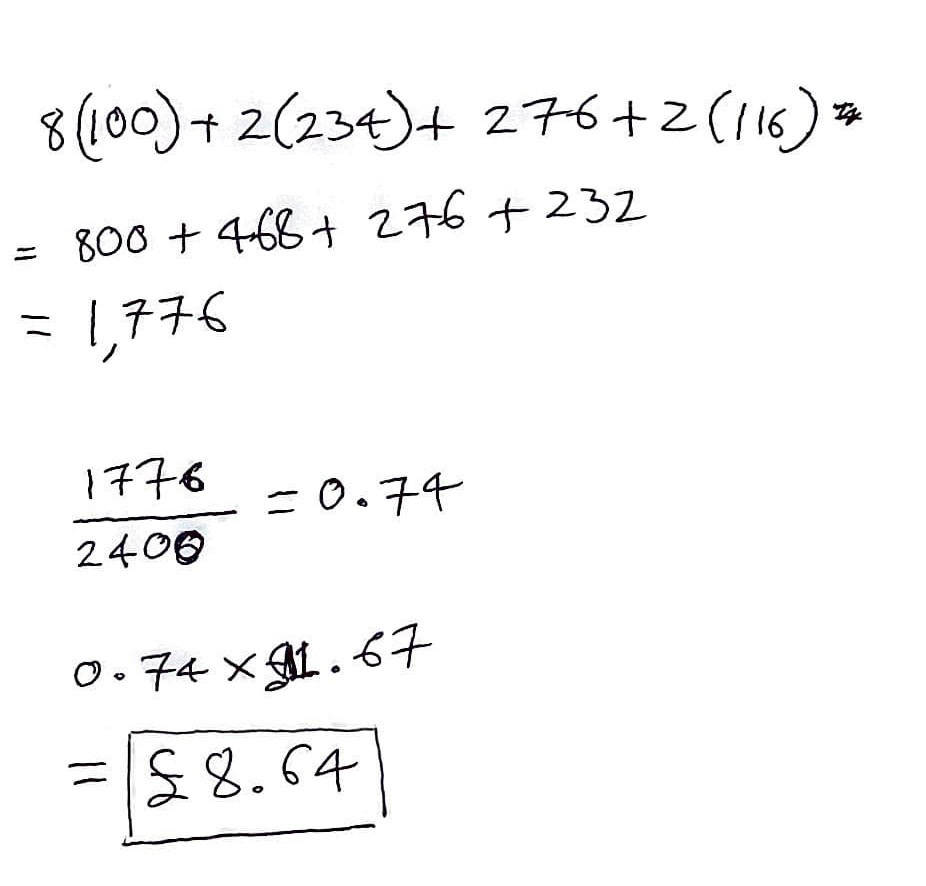

Instead of purchasing each component separately I needed to tessellate the components together as purchasing multiple custom cut sheets would increase the price.

The following information summarises my investigation into material sheet costs:

Material costs using standard sized sheets from external providers

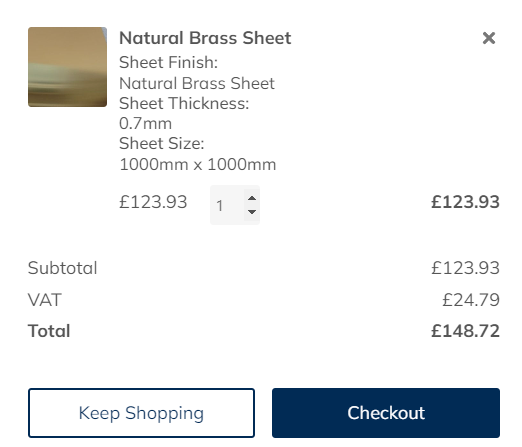

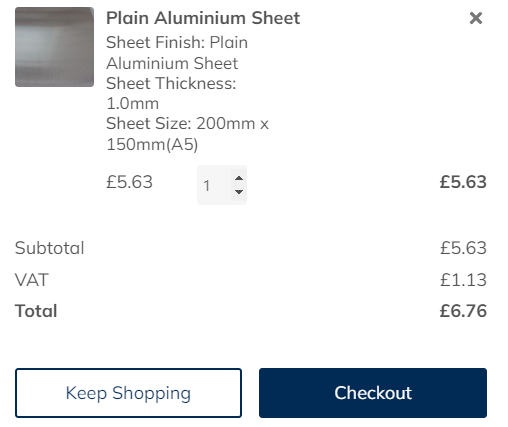

A more realistic approach to costing my work outside of university would be to purchase standard sheet sizes. This would require initial capital to purchase the material and a sizable investment into the business. I have looked at sourcing sheets the closest to the area required for this project but if the business was more developed and had higher capital to invest in material stock, I would most likely be buying the largest sheets and in bulk as I could, which would reduce the cost per square centimetre.

I have calculated the cost by taking a percentage of the sheets required to produce the work using the tessellated sizes above. This is a slightly unrealistic way to work out how much I would be using out of a sheet, as not all the remaining sheet will be usable for future work. However, all off cuts and scrap metal could be used in the material testing and development stages in future projects, so it wouldn't go to waste.

The following information summarises my investigation into material sheet costs:

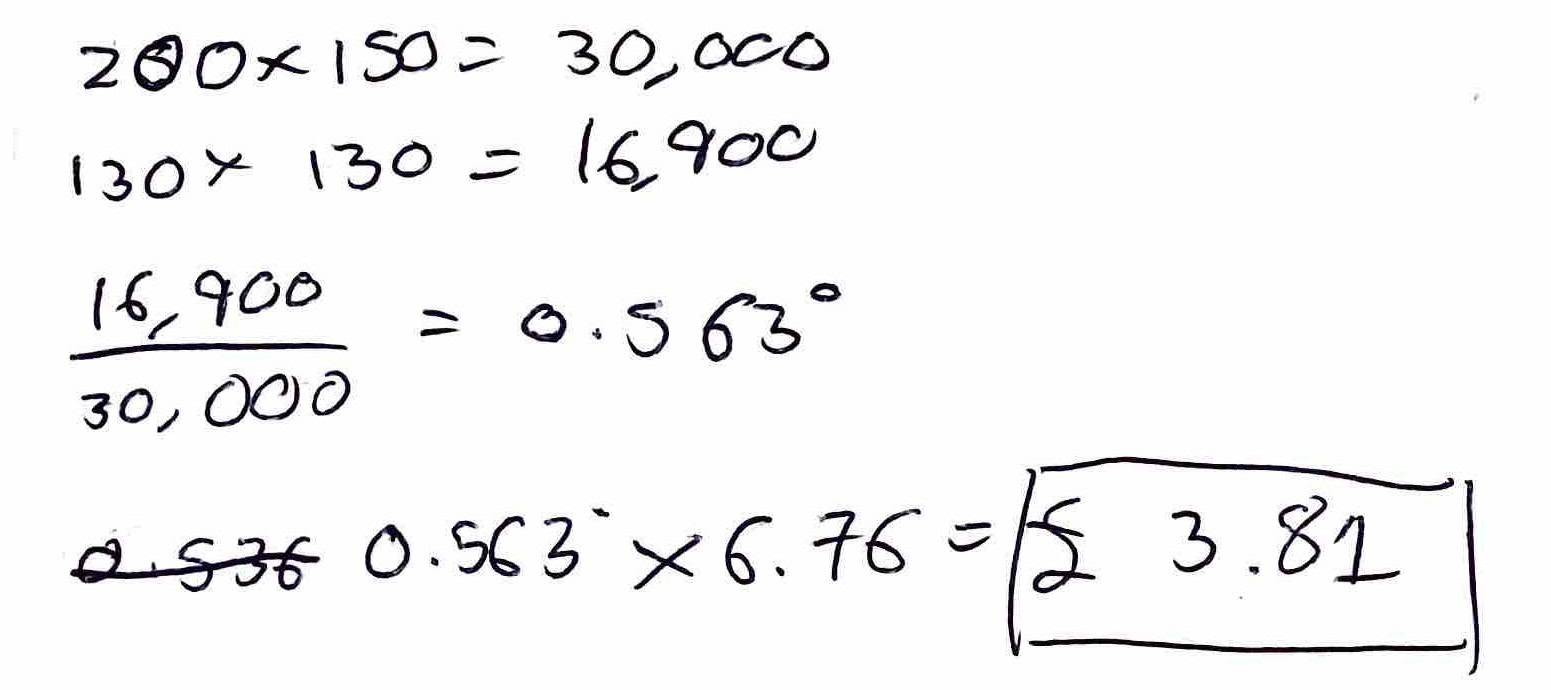

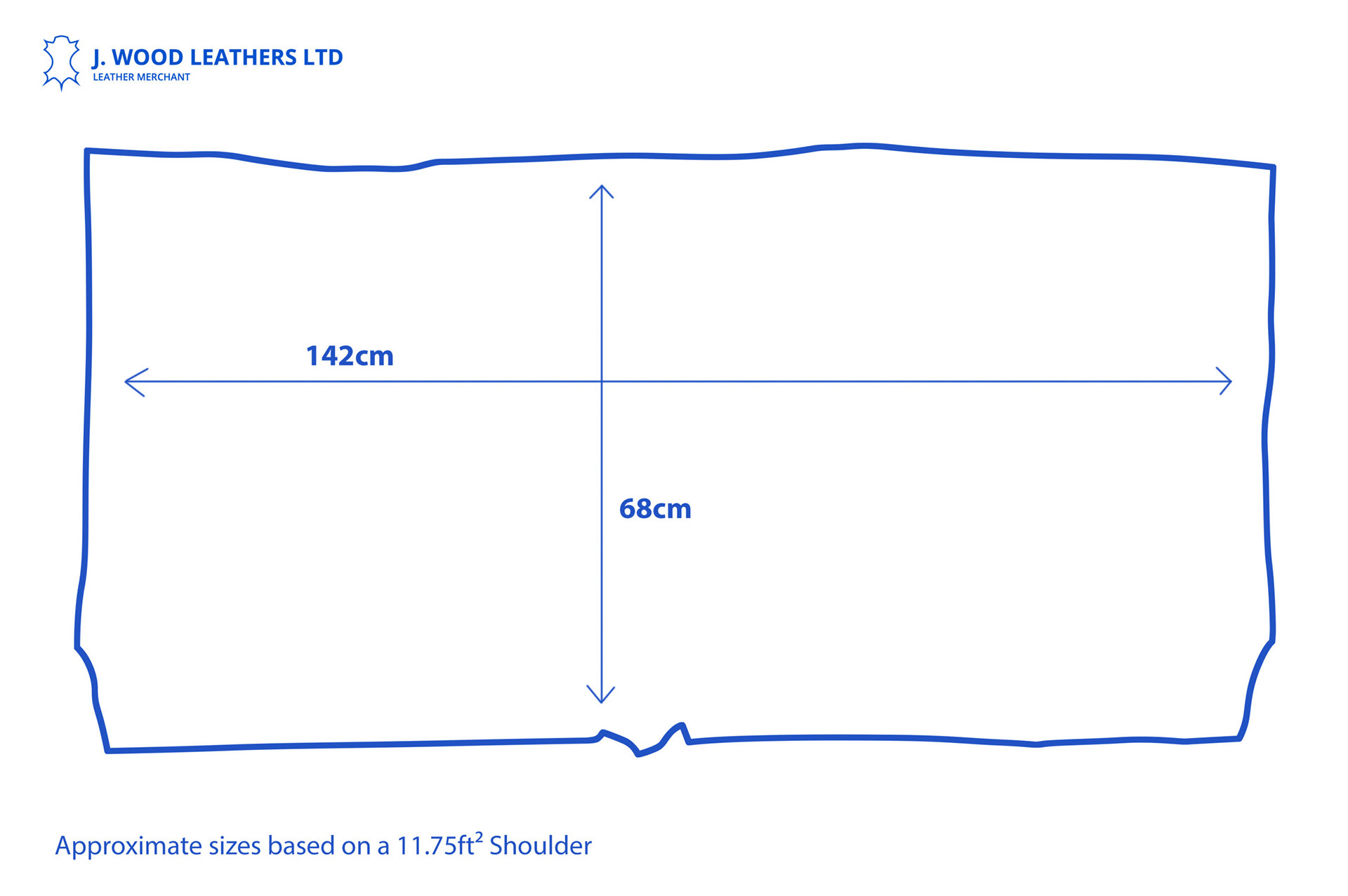

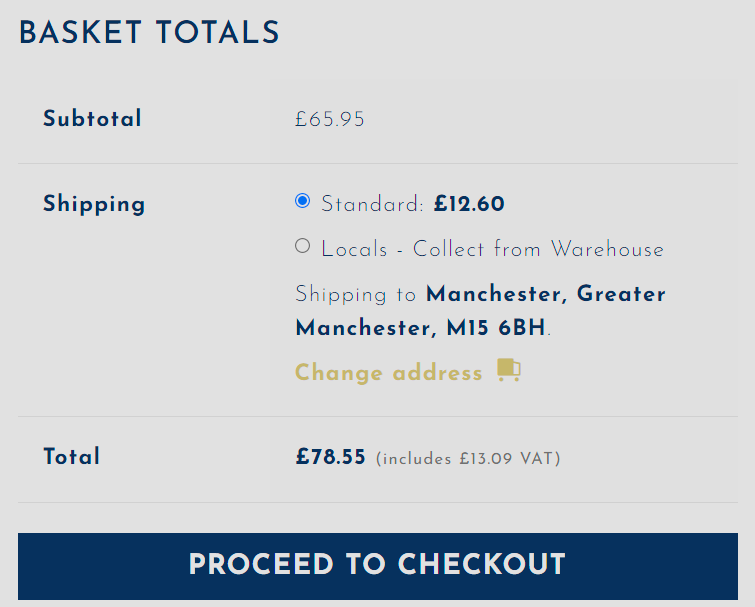

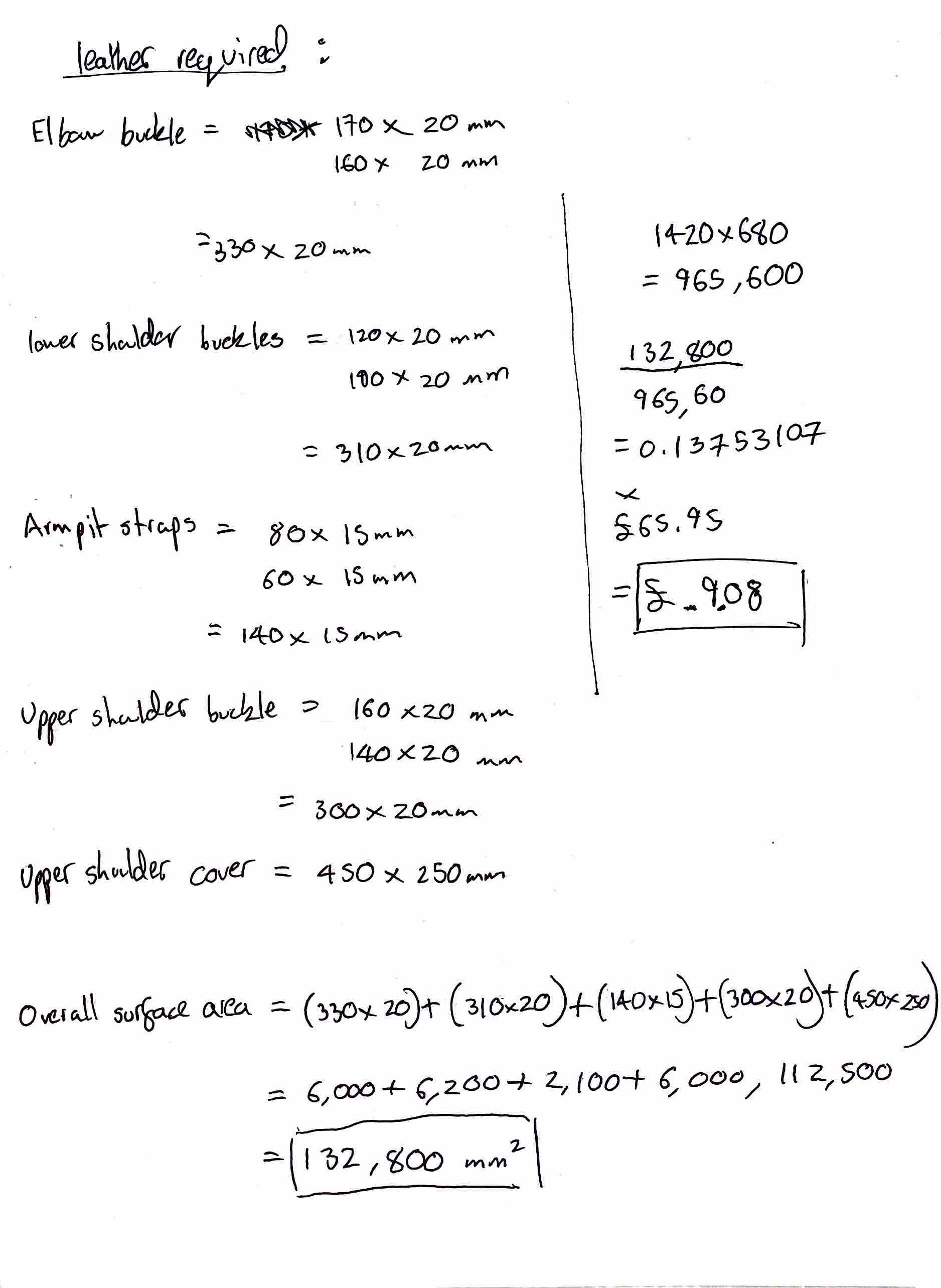

I had to look at costing leather form other sources than the scrap store leather off cuts I brought from Wiltshire Scrapstore. All material purchases from the scrap store cannot be used for commercial making. Therefore, I investigated leather suppliers that sell Veg tanned leather. I could of buy leather strips with the desired length from other companies however, I need a larger sheet to create the upper shoulder area.

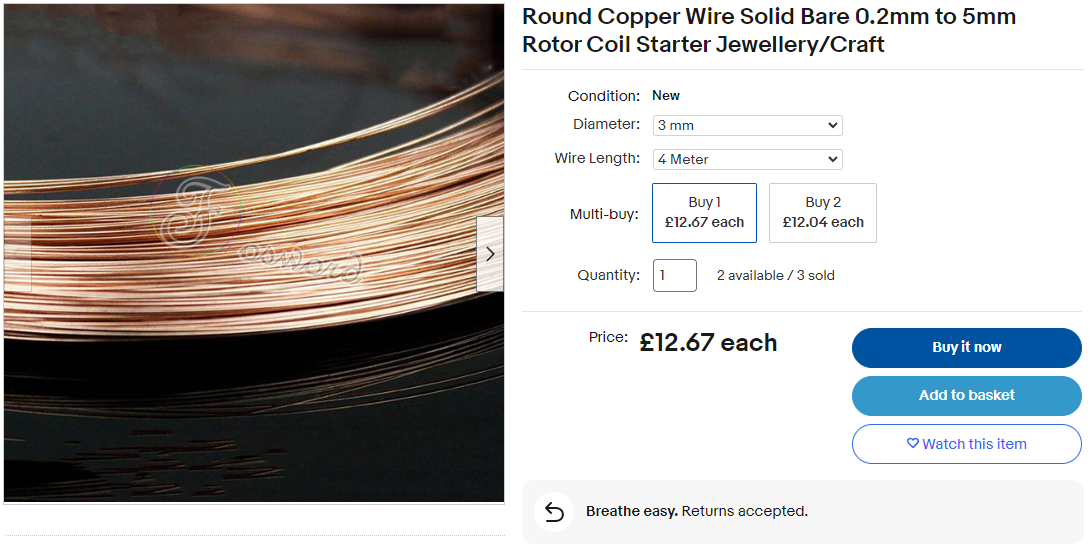

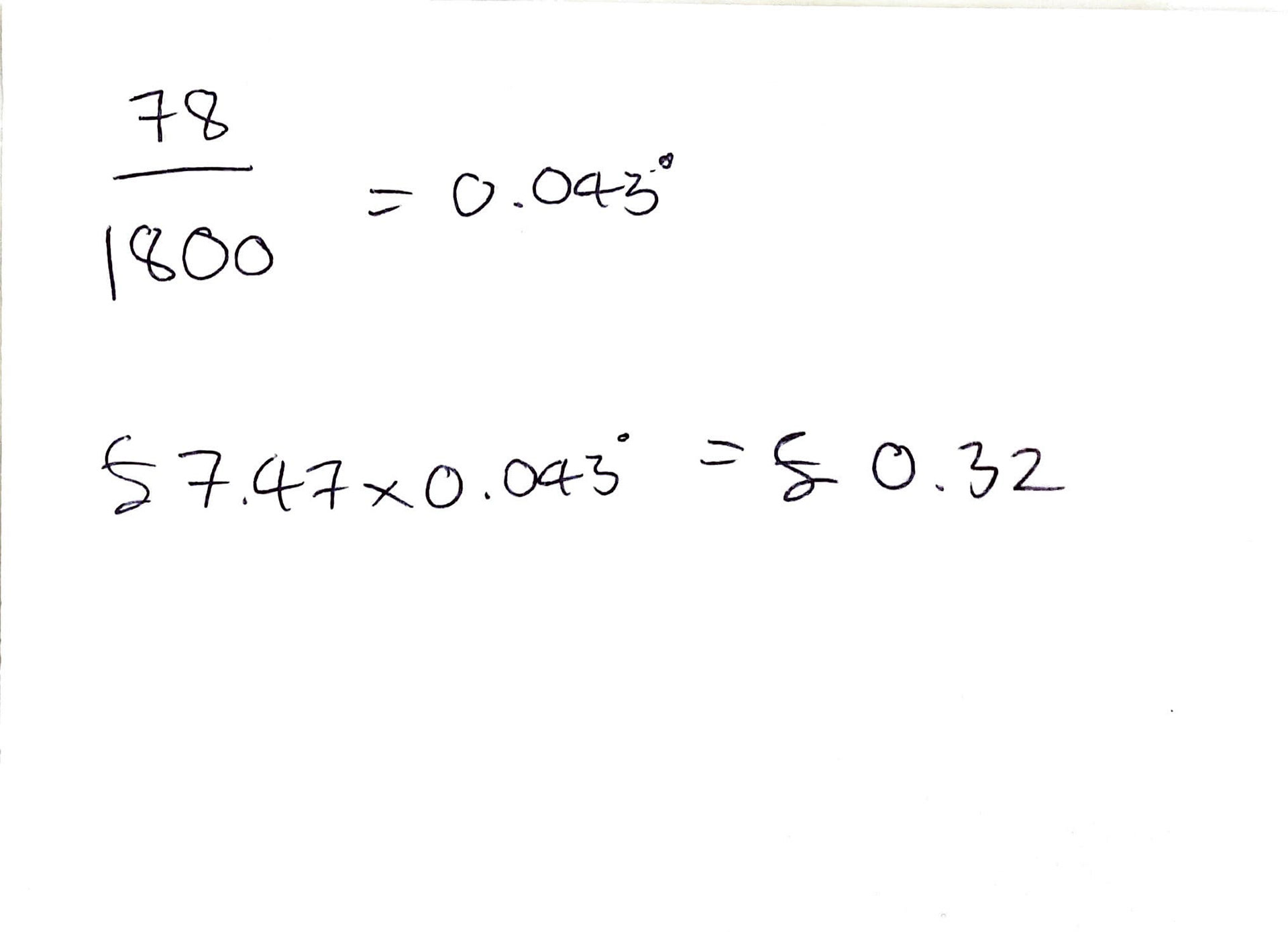

The most cost-effective way to purchase the copper wire is through eBay:

Material costing for display plinth using external vendors

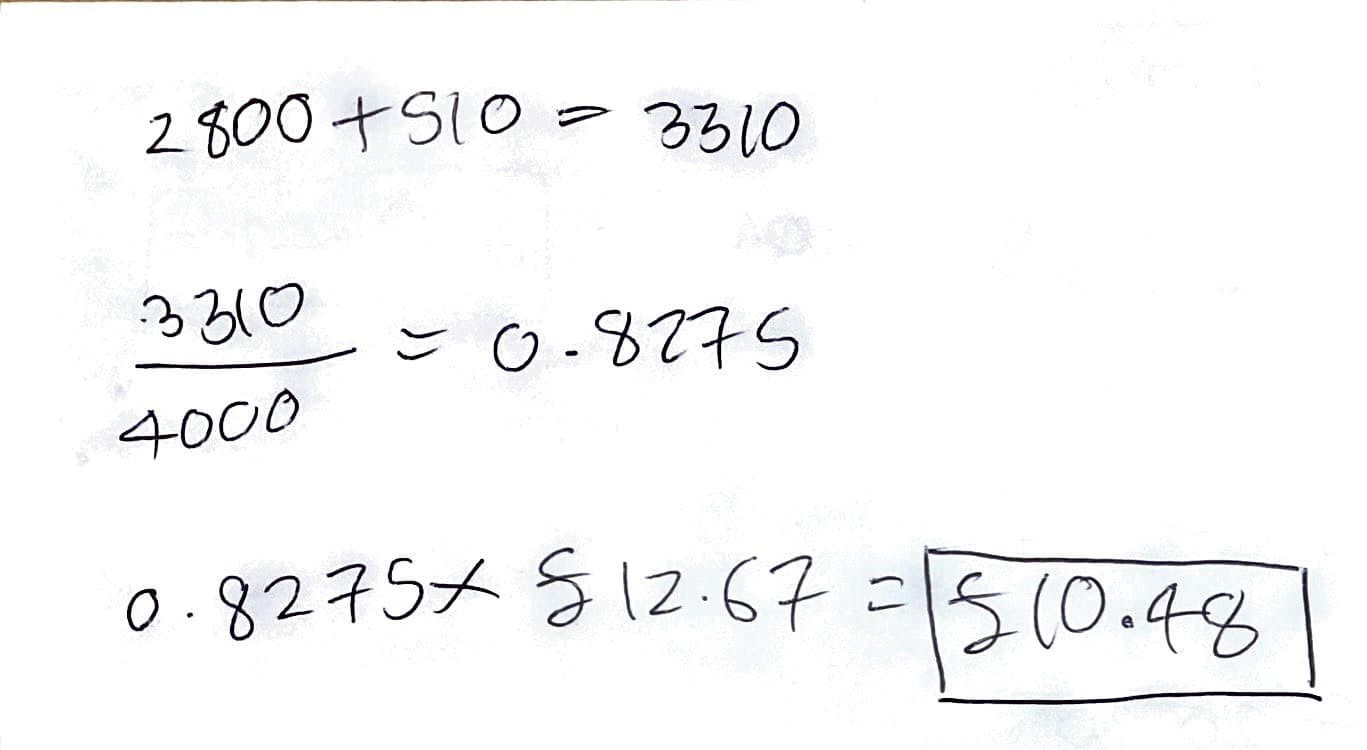

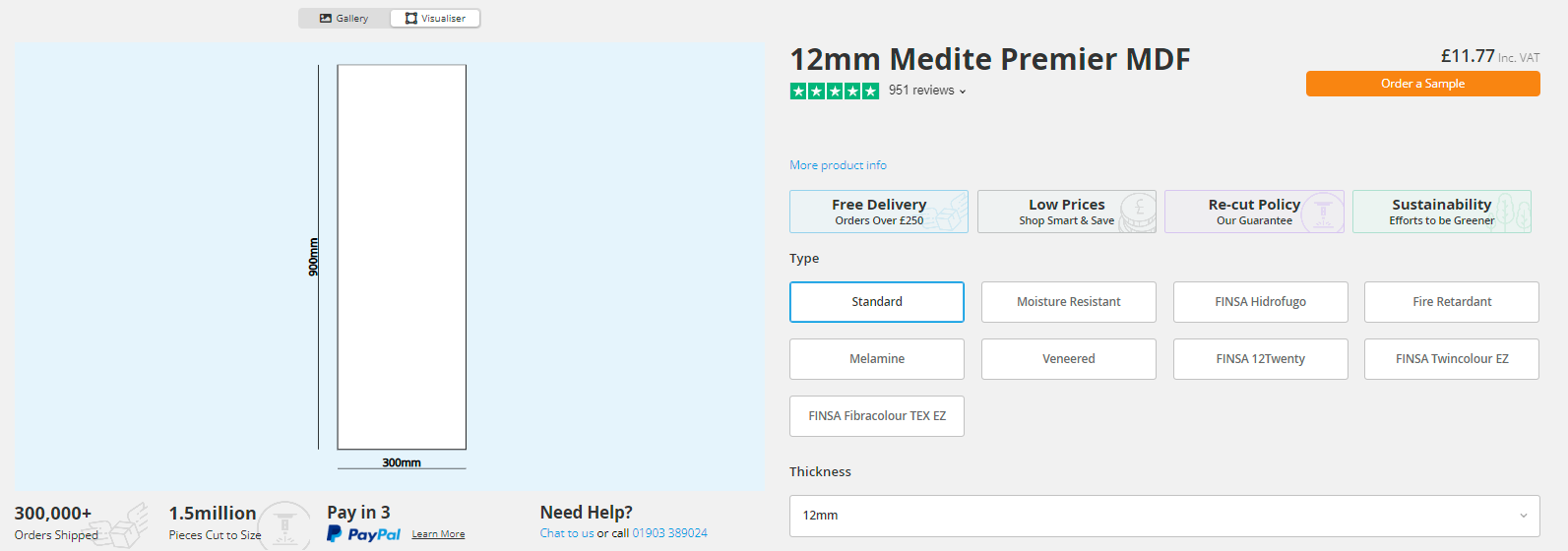

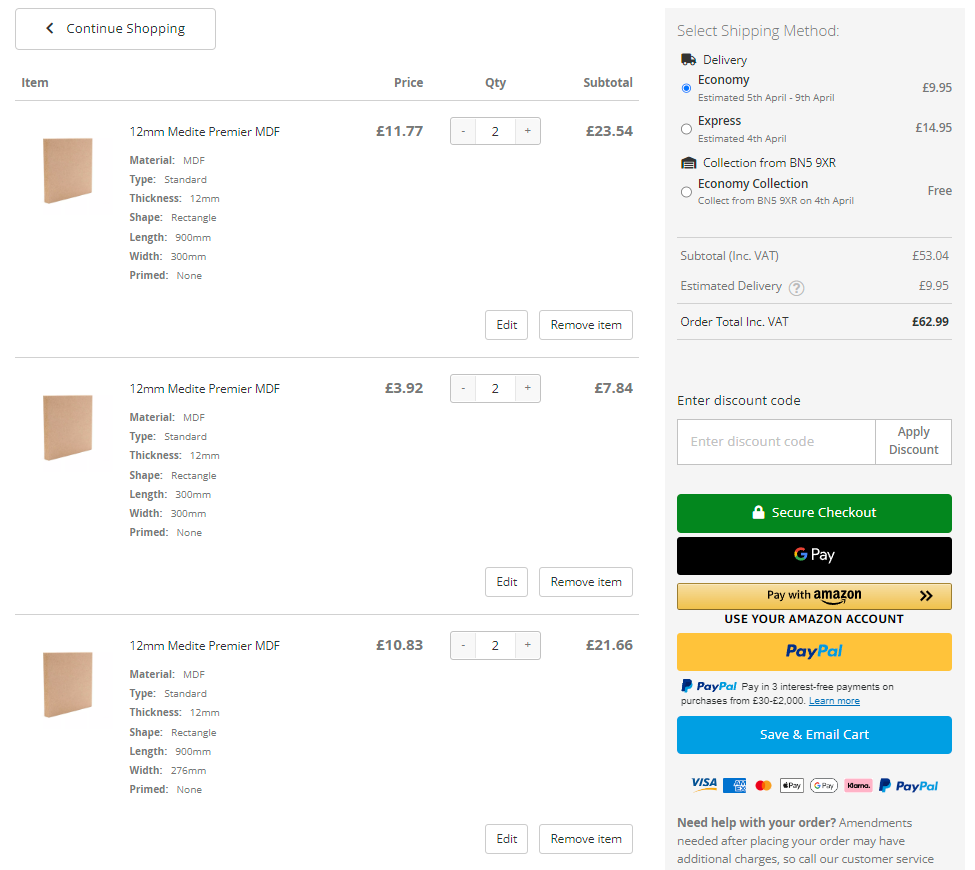

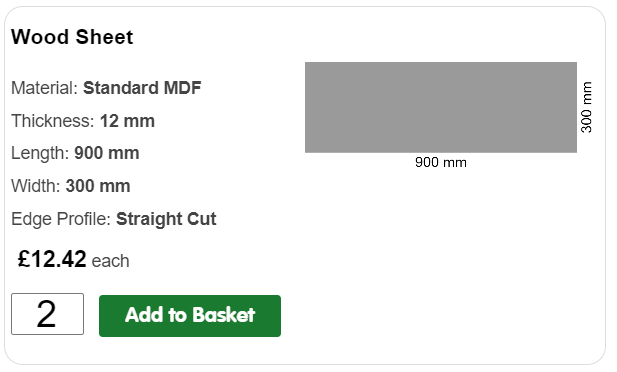

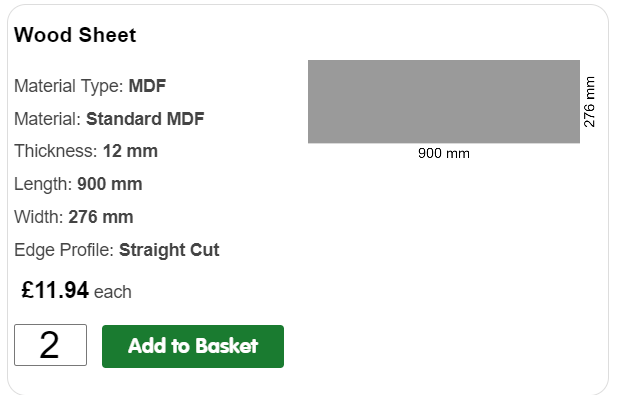

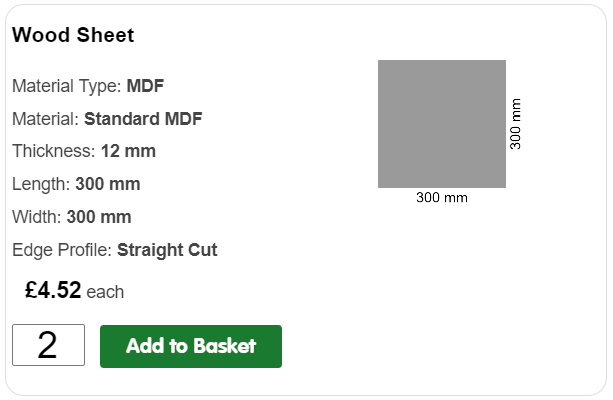

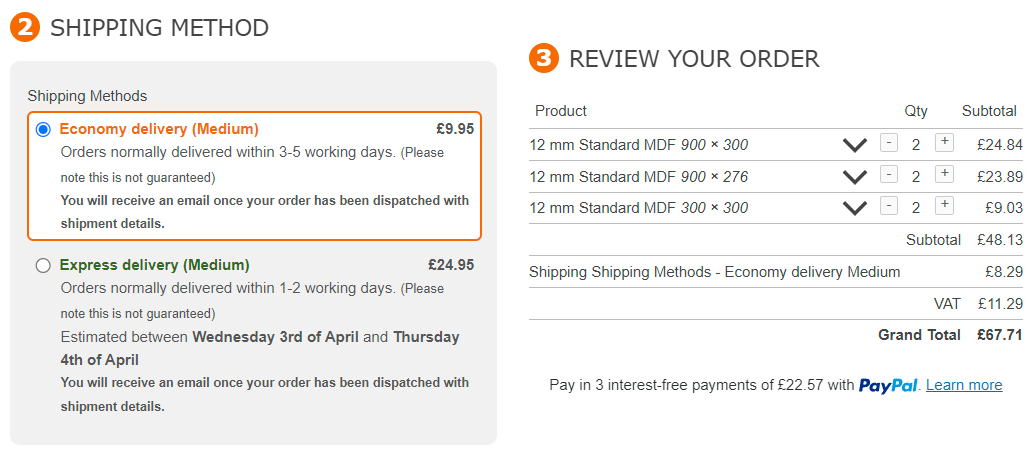

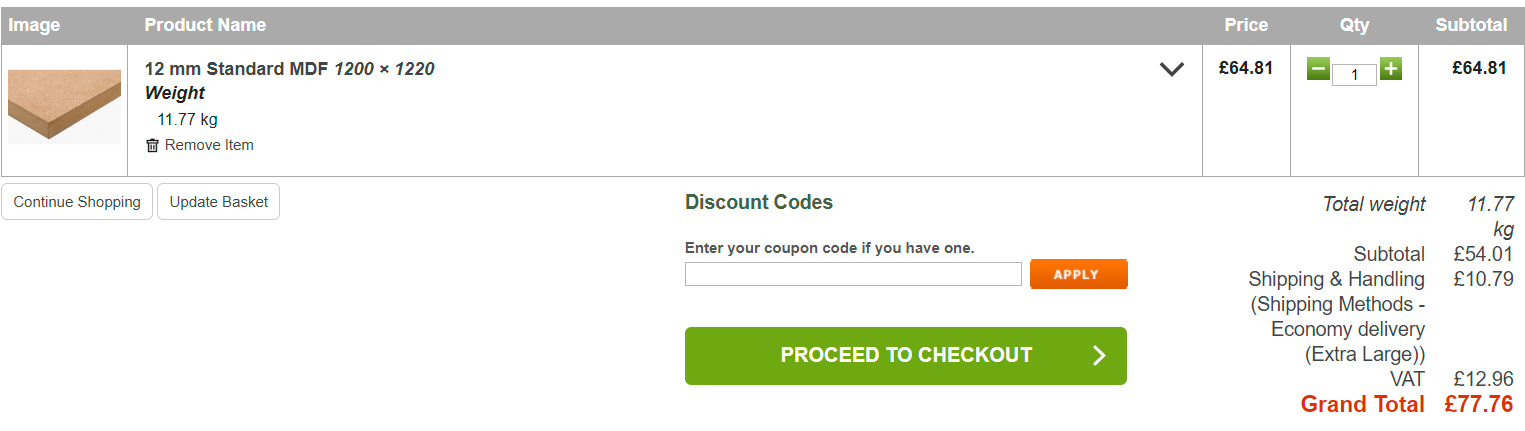

To cost the plinth I first looked at using sites that cut the MDF to the exact size to replicate the university’s system. I decided that the MDF was the only material that would need to be sourced this way as I could very easily cut up the pine sections myself from standard lengths sold at hardware stores.

The method of sourcing the MDF to the exact sizes needed to build the plinth was very expensive so I compared it to purchasing the overall tessellated size required and the price increased further, probably due to delivering such a large object.

These methods of purchasing the exact MDF size needed for the project is way too expensive and I wouldn't purchase material in this way when outside of university.

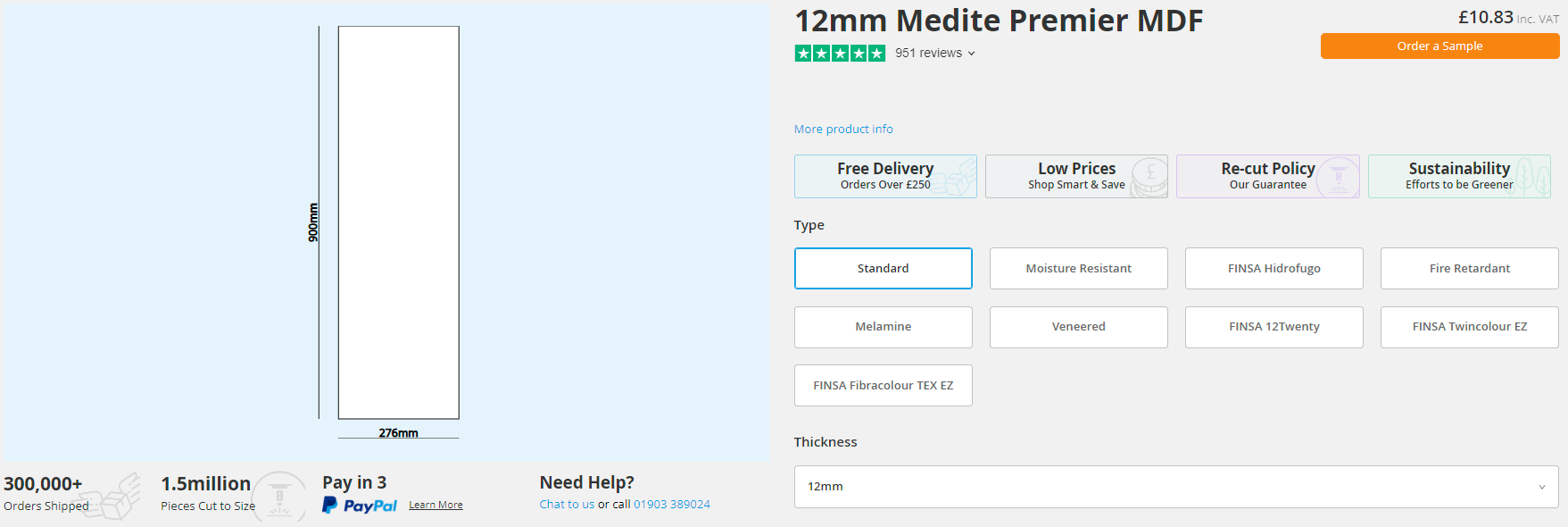

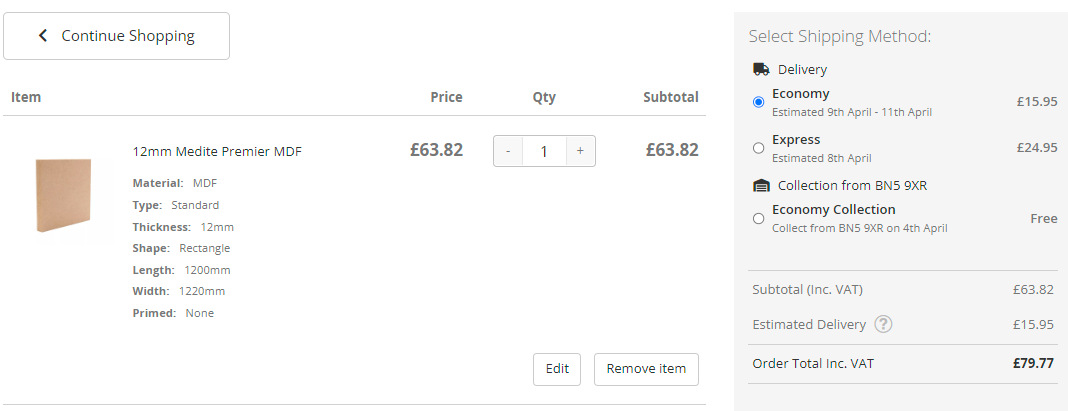

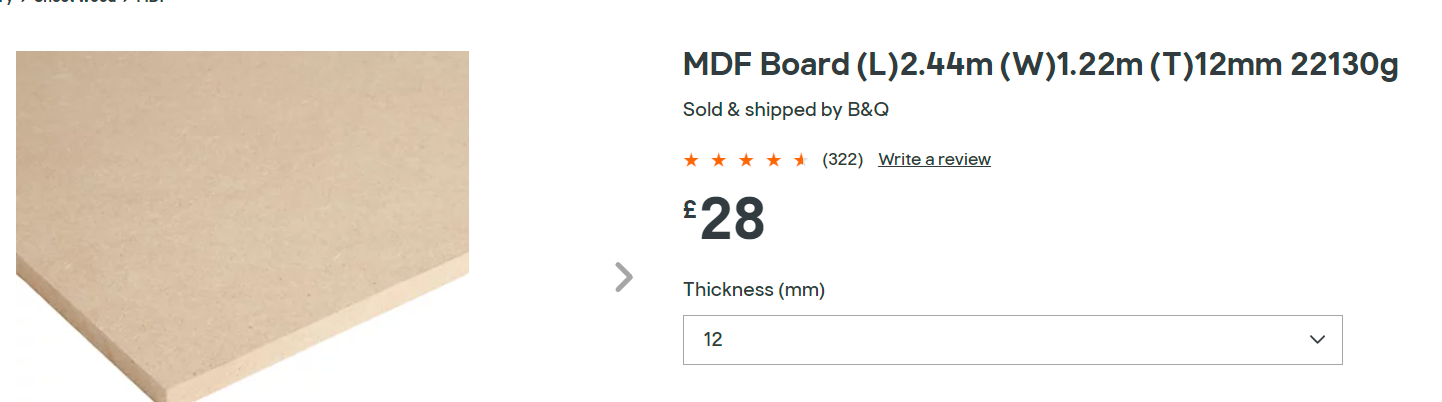

Material costs using standard sized sheets from external providers for the plinth

Rather than purchasing the exact quantity of wood needed to build the plinth, I would source the material from hardware stores such as B&Q or Wickes, as I wouldn't need high quality materials from specialist industry suppliers. I would then use the same system of working out the percentage used as the metal sheets to calculate the cost of the work, and the left-over material could become stock in the business for future projects.

£5.20 x 0.4 = £2.08

Sourcing the plinth in alternative ways

Another option would be to outsource the production of the plinth. This would create a higher quality product than I could create myself and save myself manufacturing time which would be better spent elsewhere.

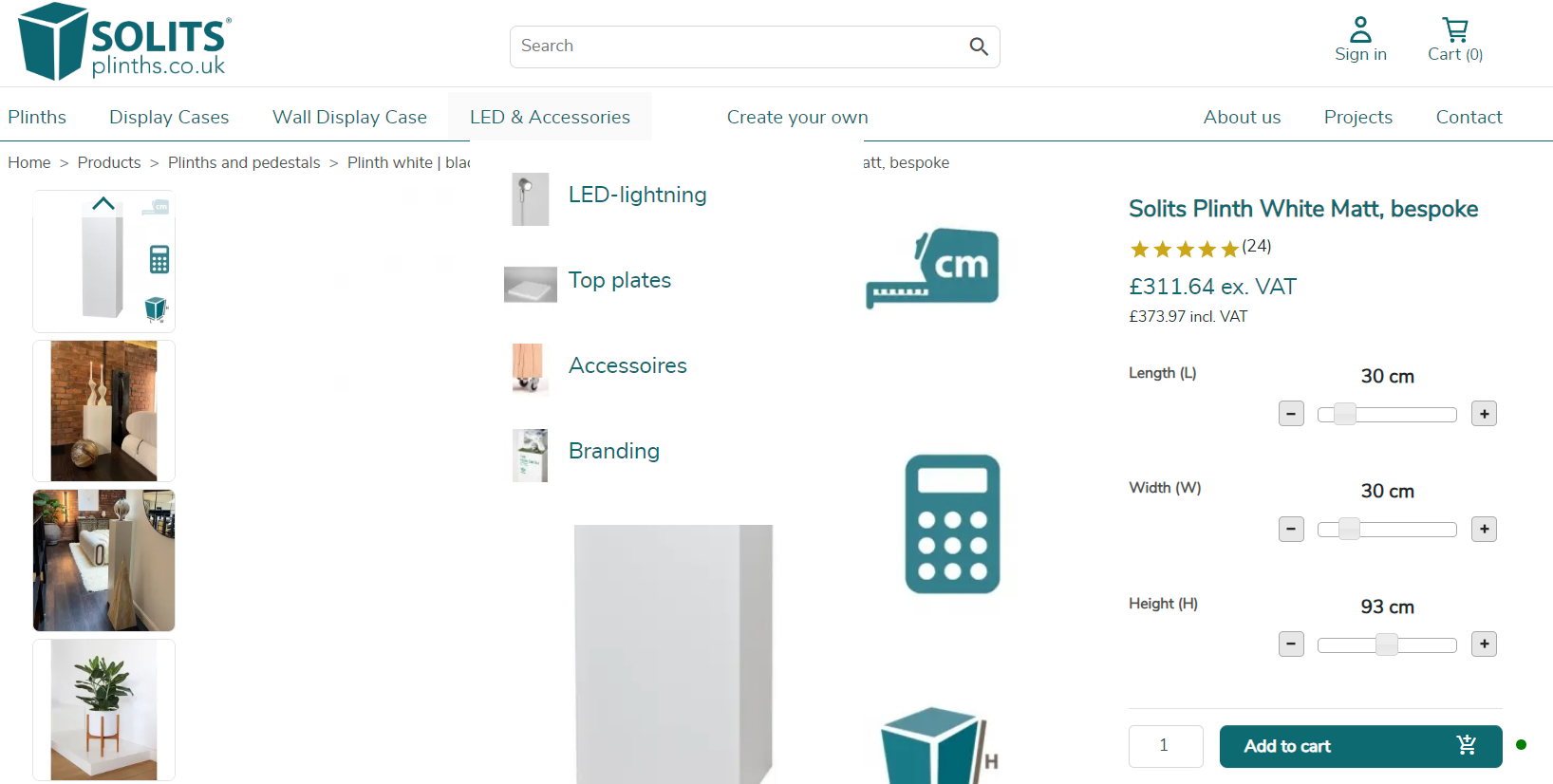

SOLITS plinths sell custom size white plinths which I could purchase the exact same size I have made myself. I would then alter it to allow the threaded bar to slot through the top and bolt into the plinth.

This is a very expensive option and wouldn't be a cost-effective way to present my work for a plinth that I probably wouldn’t sell alongside the work.

Plinths and Pedestals are a company that sells a range of sized plinths for purchase or hire. I would have to buy it as I need to drill holes into it. However, I could alter the way that the cast arm is secured to the plinth by potentially setting it into a block of plaster or concrete that would sit on top of the plinth. My main concern with this method is the work toppling over as it wouldn’t be secured to a hired plinth.

Once again this is a costly way of presenting my work and therefore, I would probably look at alternative display options.

However, if I was showing my work at Collect through the gallery FIVE I would most likely be provided a plinth to present my work on. This would fit in with the rest of the gallery display and reduce the cost of my work as the display element would be covered by the gallery. The only concern would be when my work is sold how it is then presented and I would potentially have to alter my presentation system to create a product that could be placed on a surface without needing to be bolted to it.

Cost of body casting

I created a body casting of my collarbone to wrist using alginate, plaster and hessian. I did this at university with the plaster technician who only charged me for the materials used.

Casting arm cost in university = £15.90

However, this cost only includes the materials used not the time spent by myself and the technician over a day to produce the cast. Therefore, adding in the labour cost of two people for a day’s work (using the average artist hourly wage from glassdoor.co.uk) a more likely cost would be £186.54.

I couldn't find anywhere that did the exact same casting area that I used, and therefore I looked at casting a full torso with arms included. This give a greater view of how the work sits on the body but also increases the price due to the larger forms and also the additional complexity.

Front torso with shoulders and upper arms = £350

After comparing the price of my body cast, which I used to display my work to showcase how it sits on my body, I wouldn't have done a personalised casting. The price is too high and too much of an investment into displaying the work. Therefore, if I was to replicate this outside of university, I would look at using another way of casting my body or capturing the general form.

Material cost without the display include

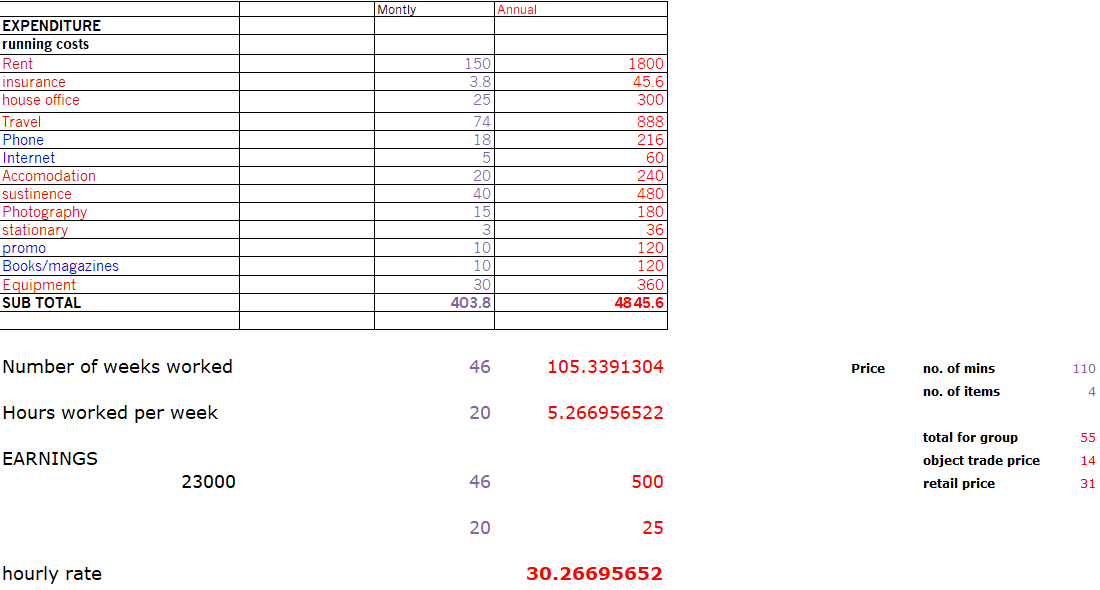

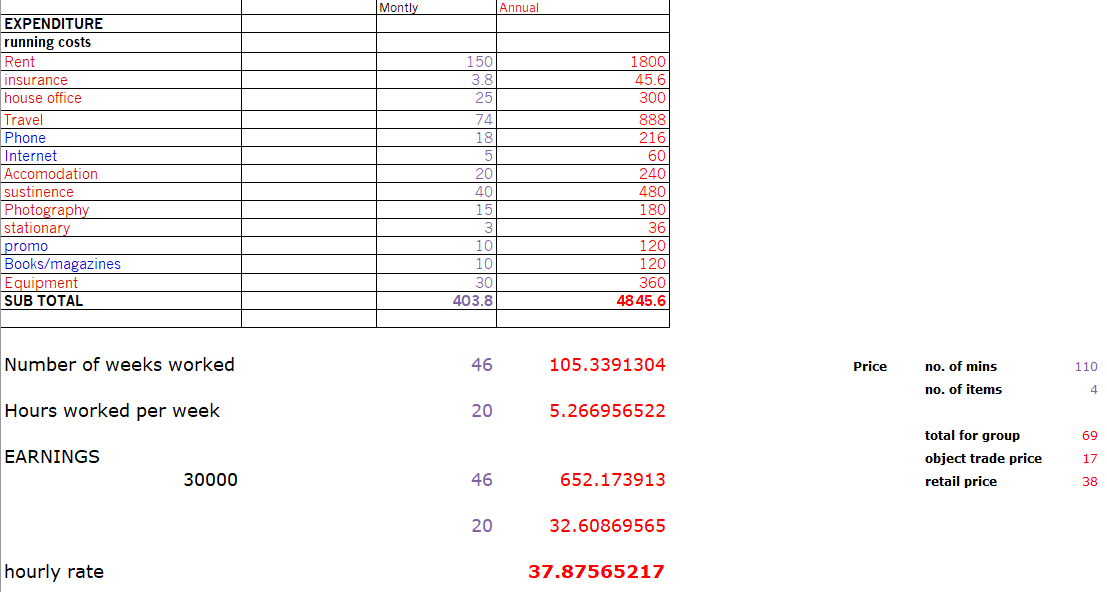

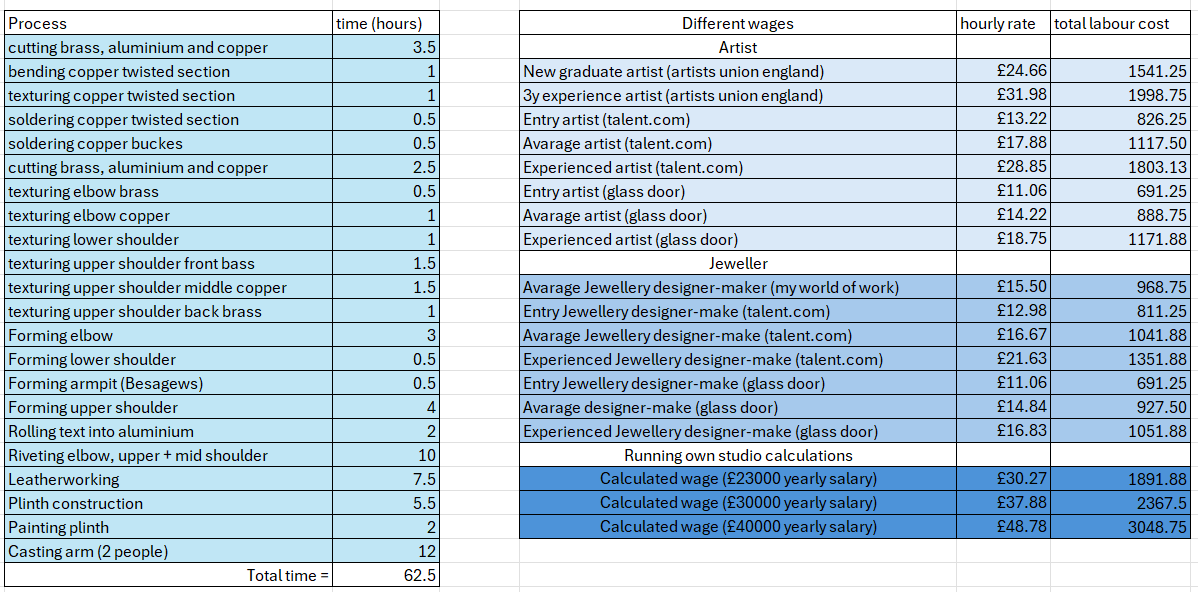

Calculating the time cost to produce my final piece

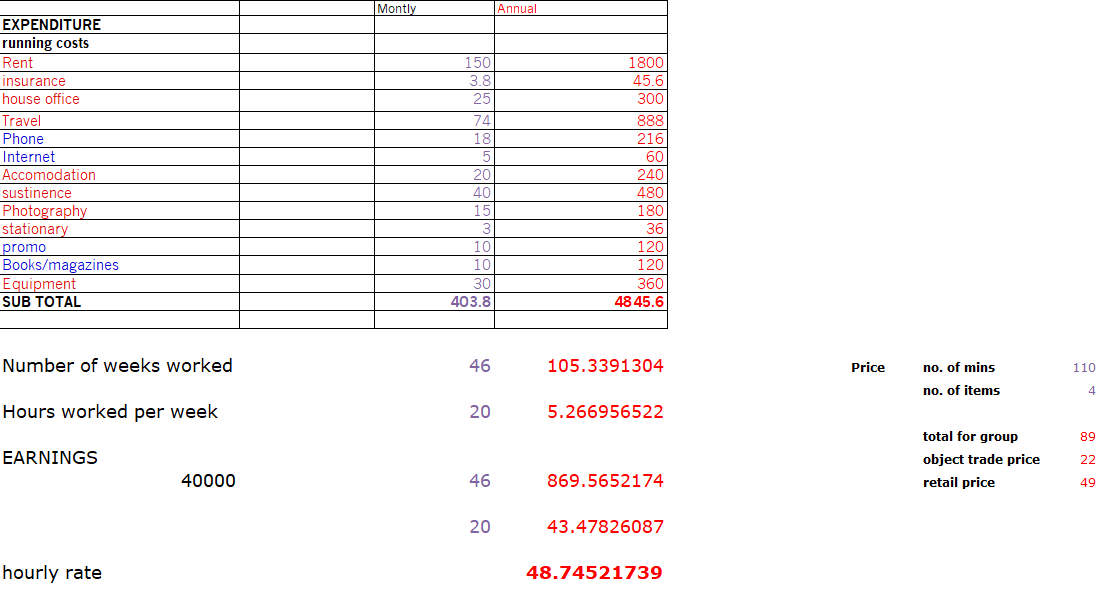

To calculate the time cost I first looked at calculating my own hourly wage as an independent maker running or hiring a studio. This is worked out through setting a yearly salary and adjusting the monthly expenses. The main cost would be the hire of a studio in Manchester which I found to be roughly £150 per month. I then compared this to artist and jewellers’ hourly wages at different stages in career and found that there was a large difference. I believe this is because the result I found wouldn't account for running a workshop but rather working for another artist who would take on this financial responsibilities.

I think that it is good to compare the industry and my own calculations wages. I have the put the Artist Union England Graduate wage as my higher end number from industry and took the average jewellery designer-make from talent.com as my lower range.

Although looking across the market is a good exercise to place myself in the market, I believe over time working as a graduate and immersed in the industry I will have a better understanding of how to charge for my time.

Calculating the time cost to produce my final piece without the plinth

I then worked out the time cost for just the artwork excluding the display as this is an element I receive from the gallery when presenting at Collect.

Final price of work

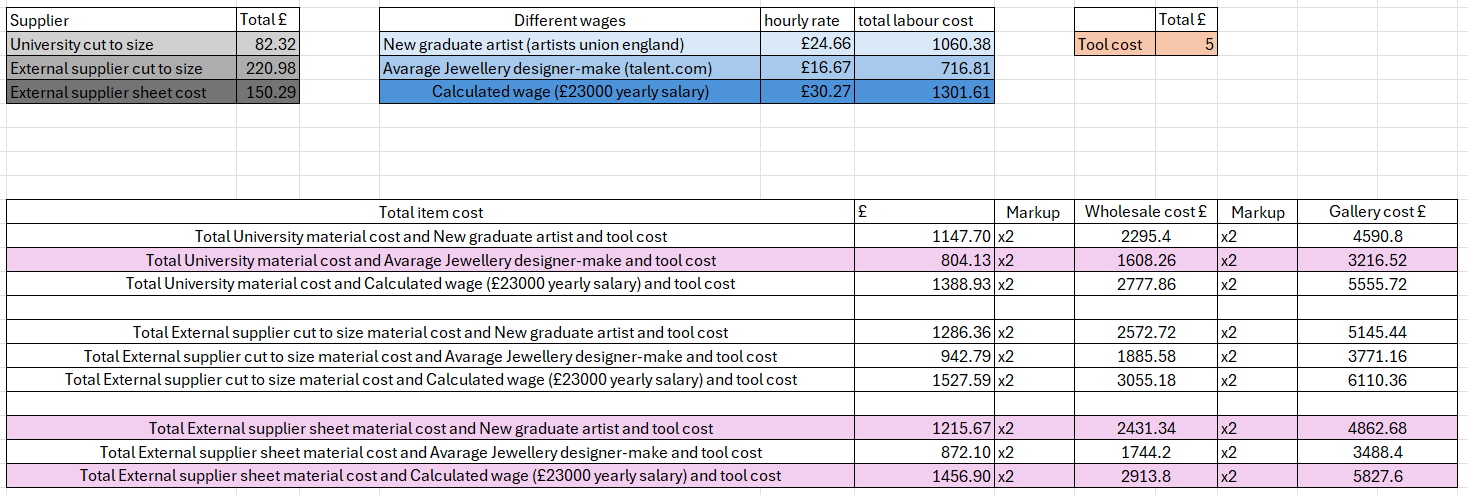

To work out my final price I first calculated the total item cost by adding up the material, tool and time costs. I then multiplied this by 2 for the standard mark up to get my wholesale cost. Finaly, I repeated this to get my gallery costs.

I calculated a range of prices looking at all the different material and labour cost differences.

I think the most appropriate price for my work now as a student is to use the university material prices and the average jewellery designer-make wage from talent.com of £16.67. Additionally, this wage takes into account that at University I don't need to include renting a studio workshop.

University gallery cost = £3216.52

If I was to make and sell this as a graduate, I think that using external supplier sheet material cost would be the most appropriate. This would require a large upfront investment into materials of £347.08 of which I would use £150.29 to make the piece. I would also look at using my own calculated hour wage of £30.27 to cover running my own studio.

Graduate gallery cost = £5867.60